Reliable integrated temperature and humidity control for rheology and dynamic mechanical analysis.

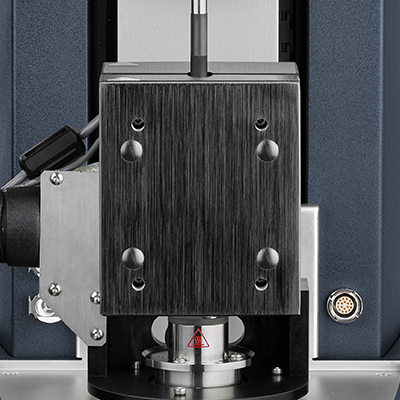

The DHR-RH Accessory is a new environmental system for the Discovery Hybrid Rheometer that enables accurate control of sample temperature and relative humidity. The DHR-RH Accessory employs a custom-designed humidity and temperature chamber that is optimized for rheological measurements. The accessory provides stable, reliable control of temperature and humidity over a wide range of operating conditions and successfully prevents condensation, a common occurrence in controlled-humidity environments which makes accurate control of relative humidity impossible.

Features and Benefits

- Uniform, reliable control of temperature and relative humidity over full operating range

- Optimized gas flow eliminates interference from laboratory conditions

- Wide variety of test geometries:

- Standard parallel plate

- Disposable parallel plate

- Annular Ring

- Surface Diffusion

- True axial solids DMA including superior film/fiber tension geometry

- Completely integrated system including native control and coordination of temperature, humidity, and rheology through powerful TRIOS software

- Innovative geometries for RH: true humidity-dependent rheology, not dominated by diffusion

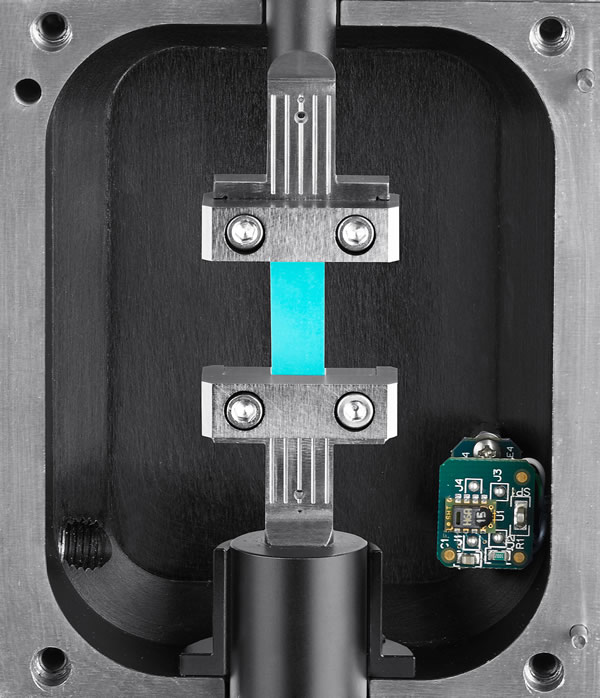

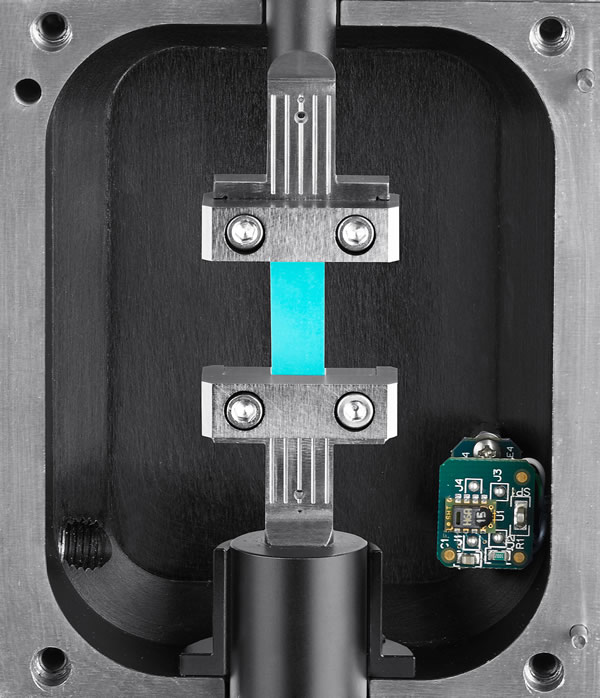

- Unique DMA mode for dynamic axial testing of films in tension

- Wide variety of test geometries:

- Standard parallel plate

- Disposable parallel plate

- Annular Ring

- Surface Diffusion

- Film/Tension

Film - Tension

Film -Tension

Annular Ring

Annular Ring

Surface Diffusion

Surface Diffusion

Disposable parallel plate

Disposable parallel plate

Standard parallel plate

Standard parallel plate

Performance

| Performance Specifications | |

| Temperature Range | 5 °C – 120 °C |

| Temperature Accuracy | ±0.5 °C |

| Heating/Cooling Rate | Maximum ±1 °C/min over entire temperature range |

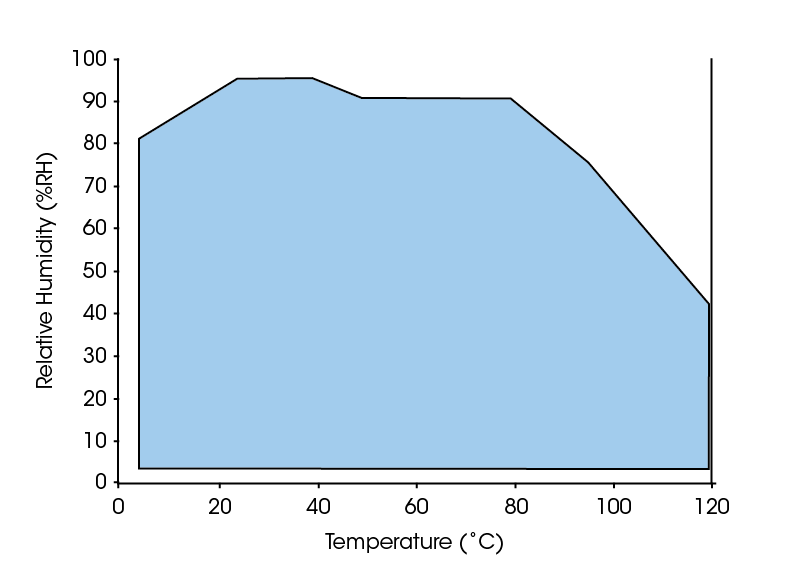

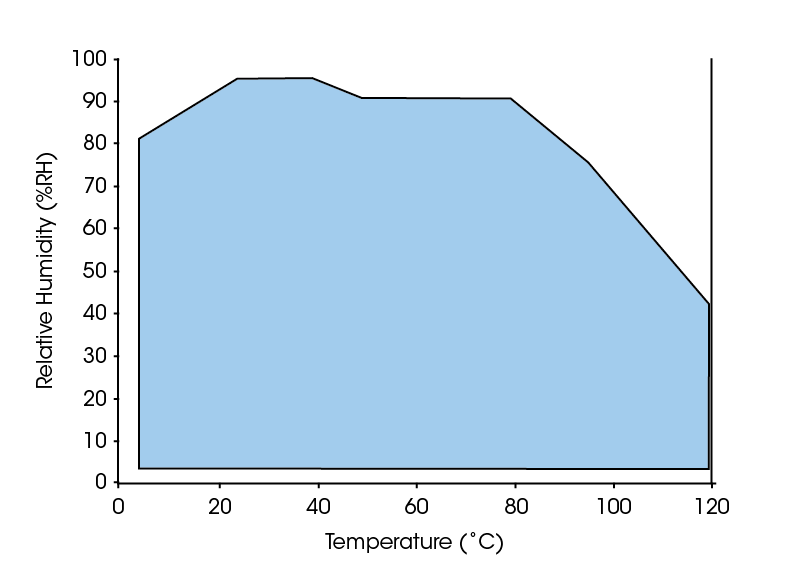

| Humidity Range | 5% to 95% (See humidity range chart) |

| Humidity Accuracy | 5-90%RH: ±3% RH >90%RH: ±5% RH |

| Humidity Ramp Rate | ±2% RH/min (fixed), both increasing and decreasing |

Paint Drying

Paint Drying

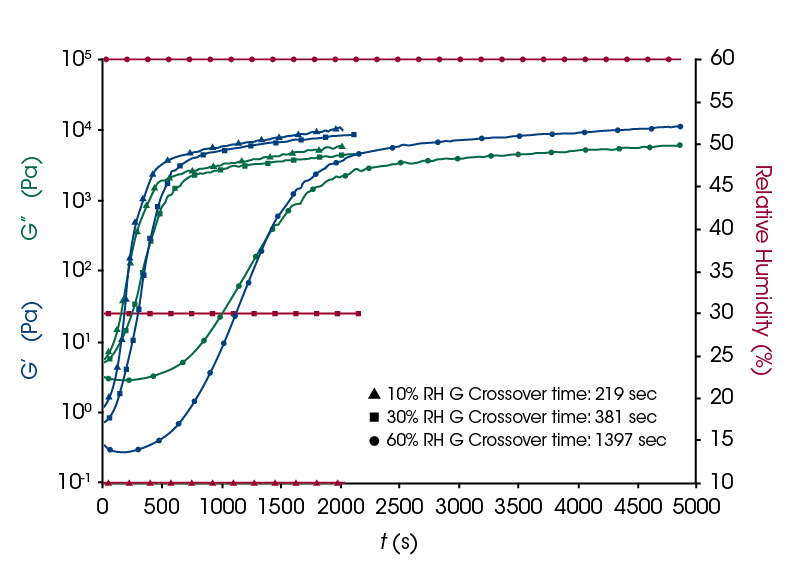

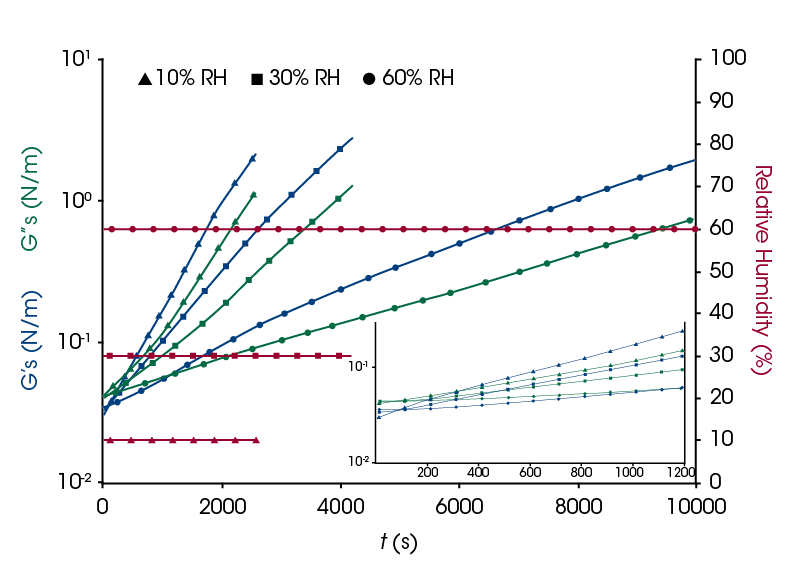

The drying kinetics of architectural coatings has an important impact on the feasibility of application and on the finished appearance. Drying time that is too fast may prevent desirable levelling, while drying that is too slow may lead to sagging. This drying process is strongly influenced by temperature and humidity. The accompanying data illustrates the drying process of a latex paint at constant temperature and three different humidity levels. A quantitative relationship may be obtained for the humidity-dependence of drying kinetics. These measurements were made using the Surface Diffusion geometry which is specifically well-suited for fast kinetic processes such as this. As paint layer thickness is quite low, the surface rheological approach to its measurements is appropriate.

Adhesive Curing

Adhesive Curing

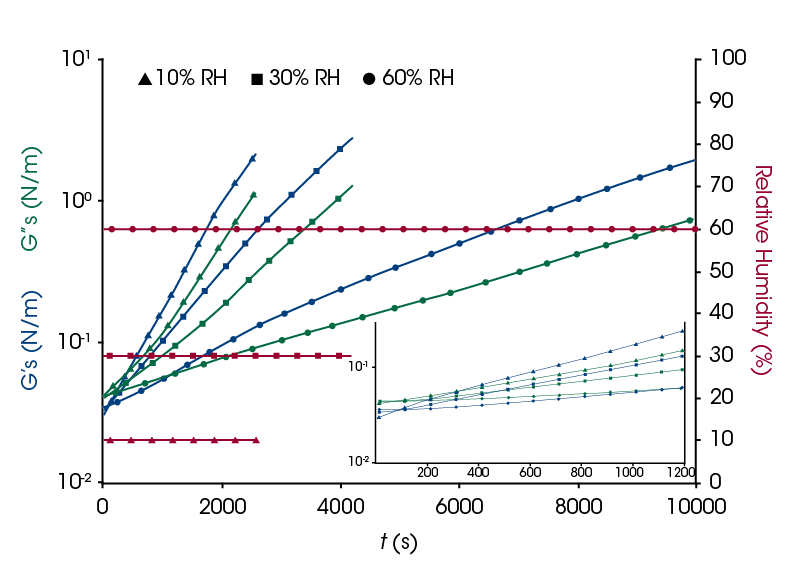

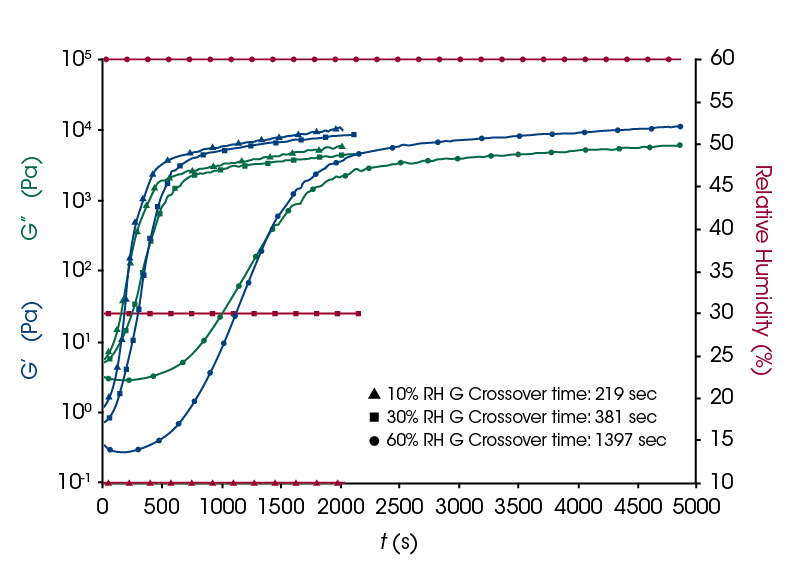

The curing process of poly(vinyl acetate) (PVA) adhesives is driven by the loss of moisture from the glue to the atmosphere. The rate of this moisture loss is governed by the ambient humidity. While curing kinetics is important, a reliable adhesive bond also depends on a sufficient modulus. The accompanying data illustrates the curing time and bulk modulus of a PVA glue at three different levels of relative humidity. The data demonstrate that higher humidity levels slow the curing process, but do not impeded the final modulus value. These measurements were performed using the Annular Ring geometry, which allows for the determination of kinetic processes that are not limited by diffusion within the sample, and also provides quantitative bulk rheological properties which are needed to evaluate adhesive performance.

Fuel Cell Membrane

Fuel Cell Membrane

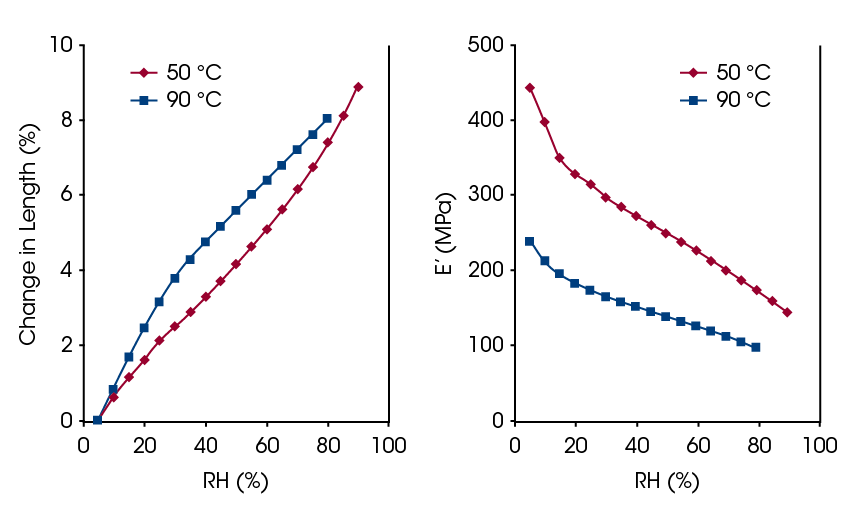

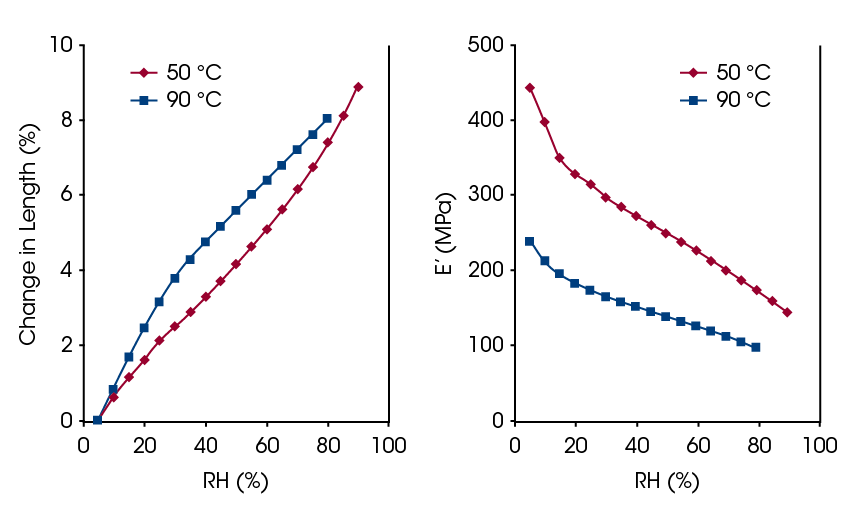

Fuel cell proton exchange membranes have performance characteristics that are strong functions of gas humidity. At low relative humidity (RH), membrane conductivity drops and the efficiency of the membranes decreases. For this reason, the operating environment is maintained at a high RH. These membranes are also strongly hygroscopic, absorbing moisture which leads to plasticizing and volumetric expansion. The axial film tension accessory was used to simultaneously measure the tensile modulus and monitor the change in sample length as a function of temperature and humidity for a commercial fluoropolymer fuel cell membrane. This information is important in designing for load and vibration tolerance, as well as dimensional stability with respect to hygroscopic expansion.

Relative Humidity Accessory Videos

|

||

- Description

-

The DHR-RH Accessory is a new environmental system for the Discovery Hybrid Rheometer that enables accurate control of sample temperature and relative humidity. The DHR-RH Accessory employs a custom-designed humidity and temperature chamber that is optimized for rheological measurements. The accessory provides stable, reliable control of temperature and humidity over a wide range of operating conditions and successfully prevents condensation, a common occurrence in controlled-humidity environments which makes accurate control of relative humidity impossible.

- Features

-

Features and Benefits

- Uniform, reliable control of temperature and relative humidity over full operating range

- Optimized gas flow eliminates interference from laboratory conditions

- Wide variety of test geometries:

- Standard parallel plate

- Disposable parallel plate

- Annular Ring

- Surface Diffusion

- True axial solids DMA including superior film/fiber tension geometry

- Completely integrated system including native control and coordination of temperature, humidity, and rheology through powerful TRIOS software

- Test Geometries

-

- Innovative geometries for RH: true humidity-dependent rheology, not dominated by diffusion

- Unique DMA mode for dynamic axial testing of films in tension

- Wide variety of test geometries:

- Standard parallel plate

- Disposable parallel plate

- Annular Ring

- Surface Diffusion

- Film/Tension

Film - Tension

Film -Tension

Annular Ring

Annular Ring

Surface Diffusion

Surface Diffusion

Disposable parallel plate

Disposable parallel plate

Standard parallel plate

Standard parallel plate

- Performance

-

Performance

Performance Specifications Temperature Range 5 °C – 120 °C Temperature Accuracy ±0.5 °C Heating/Cooling Rate Maximum ±1 °C/min over entire temperature range Humidity Range 5% to 95% (See humidity range chart) Humidity Accuracy 5-90%RH: ±3% RH

>90%RH: ±5% RHHumidity Ramp Rate ±2% RH/min (fixed),

both increasing and decreasing - Applications

-

Paint Drying

Paint Drying

The drying kinetics of architectural coatings has an important impact on the feasibility of application and on the finished appearance. Drying time that is too fast may prevent desirable levelling, while drying that is too slow may lead to sagging. This drying process is strongly influenced by temperature and humidity. The accompanying data illustrates the drying process of a latex paint at constant temperature and three different humidity levels. A quantitative relationship may be obtained for the humidity-dependence of drying kinetics. These measurements were made using the Surface Diffusion geometry which is specifically well-suited for fast kinetic processes such as this. As paint layer thickness is quite low, the surface rheological approach to its measurements is appropriate.

Adhesive Curing

Adhesive Curing

The curing process of poly(vinyl acetate) (PVA) adhesives is driven by the loss of moisture from the glue to the atmosphere. The rate of this moisture loss is governed by the ambient humidity. While curing kinetics is important, a reliable adhesive bond also depends on a sufficient modulus. The accompanying data illustrates the curing time and bulk modulus of a PVA glue at three different levels of relative humidity. The data demonstrate that higher humidity levels slow the curing process, but do not impeded the final modulus value. These measurements were performed using the Annular Ring geometry, which allows for the determination of kinetic processes that are not limited by diffusion within the sample, and also provides quantitative bulk rheological properties which are needed to evaluate adhesive performance.

Fuel Cell Membrane

Fuel Cell Membrane

Fuel cell proton exchange membranes have performance characteristics that are strong functions of gas humidity. At low relative humidity (RH), membrane conductivity drops and the efficiency of the membranes decreases. For this reason, the operating environment is maintained at a high RH. These membranes are also strongly hygroscopic, absorbing moisture which leads to plasticizing and volumetric expansion. The axial film tension accessory was used to simultaneously measure the tensile modulus and monitor the change in sample length as a function of temperature and humidity for a commercial fluoropolymer fuel cell membrane. This information is important in designing for load and vibration tolerance, as well as dimensional stability with respect to hygroscopic expansion.

- Videos

-

Relative Humidity Accessory Videos

Relative Humidity Accessory for the Discovery Hybrid Rheometer.

Relative Humidity Accessory Photo Gallery