Rheology is Maza: Unveiling the Secrets of Flowing Rangoli Colors

Part of our Rheology is Fun series! This month, we’re celebrating Diwali so Rheology is Maza – fun in Hindi.

Behbood Abedi

October 28, 2024

Powders are a big part of everyday life, from baking and laundry to cosmetics and pharmaceuticals. Understanding powder rheology—how powders flow and deform—is crucial for optimizing their use in various applications. This knowledge helps industries maintain consistency and product quality.

As October ends and Diwali excitement fills the air, there’s a fun and colorful use of powders: the vibrant tradition of rangoli! This art form uses colorful powders to create intricate designs, symbolizing prosperity and welcoming the goddess of wealth and good luck. To achieve those beautiful, detailed designs, the powders need specific rheological properties—and that’s where powder rheology comes in.

Rangoli colors are as vibrant as Diwali itself, each adding joy to the festivities. Creating rangoli designs is a fun experience, especially with a variety of powders. When creating rangoli, you’ve probably noticed that sometimes, even when you get powders from the same factory, some colors flow smoothly while others can be a bit stubborn. This could be due to differences in additives and pigment properties. Differences in flow behavior due to things like additives and pigments are part of what powder rheology can help us understand.

As Diwali approached, we got our hands on five vibrant powders – red, blue, green, yellow, and white – all from the same factory. We thought, “Why not study their powder rheology and see how they behave?” Cool, right? So, we set up a little experiment in our backyard rheology lab using our powder rheology accessory.

The Great Powder Showdown: Flow Adventures!

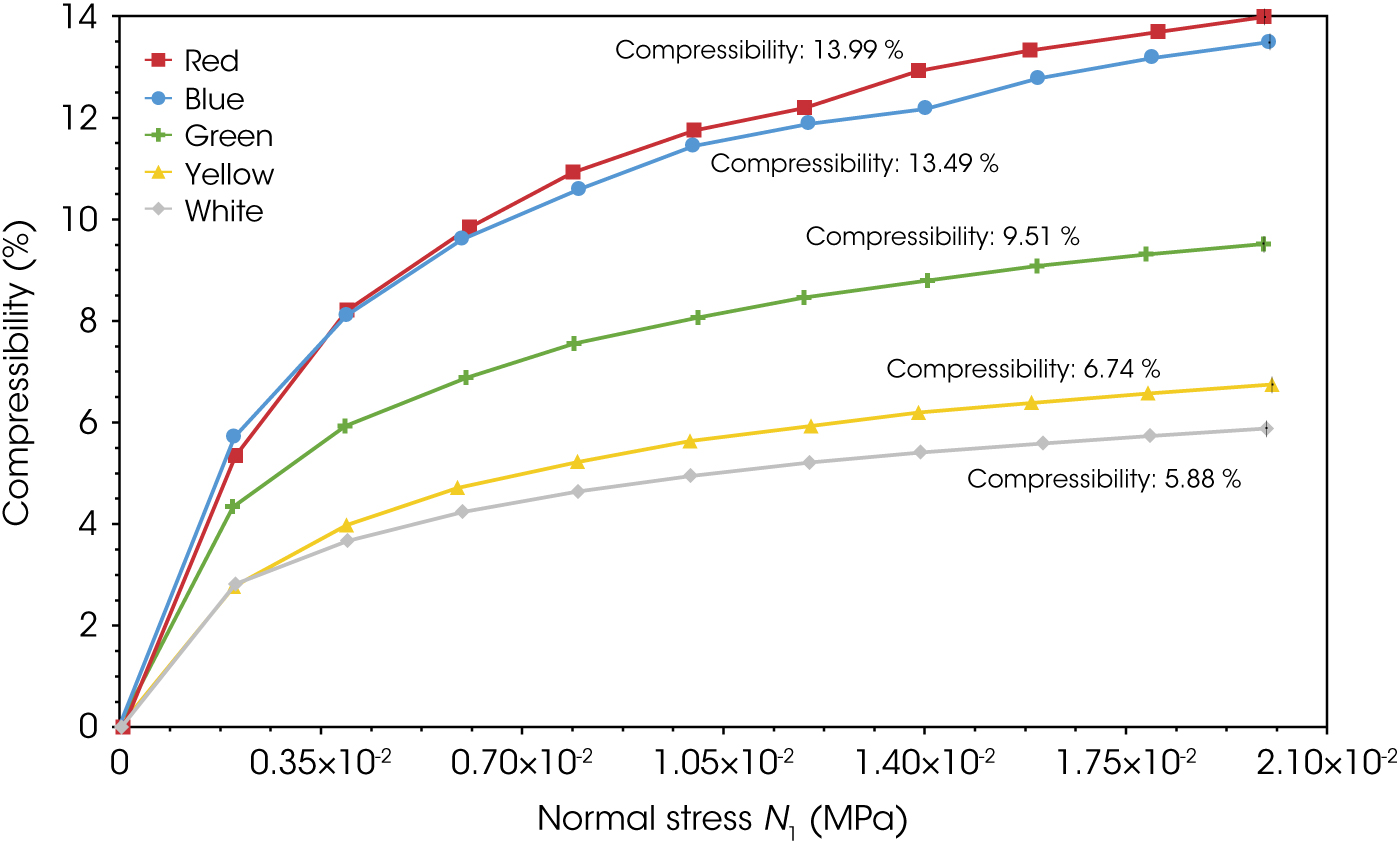

First up, we tested how well these powders could be compressed (see Fig. 1). It was fascinating to watch the blue and red powders compress almost twice as much as the white and yellow ones. These differences were noticeable when we pressed the powder on our rangoli designs, too. The green powder? It landed somewhere in between, not wanting to pick sides.

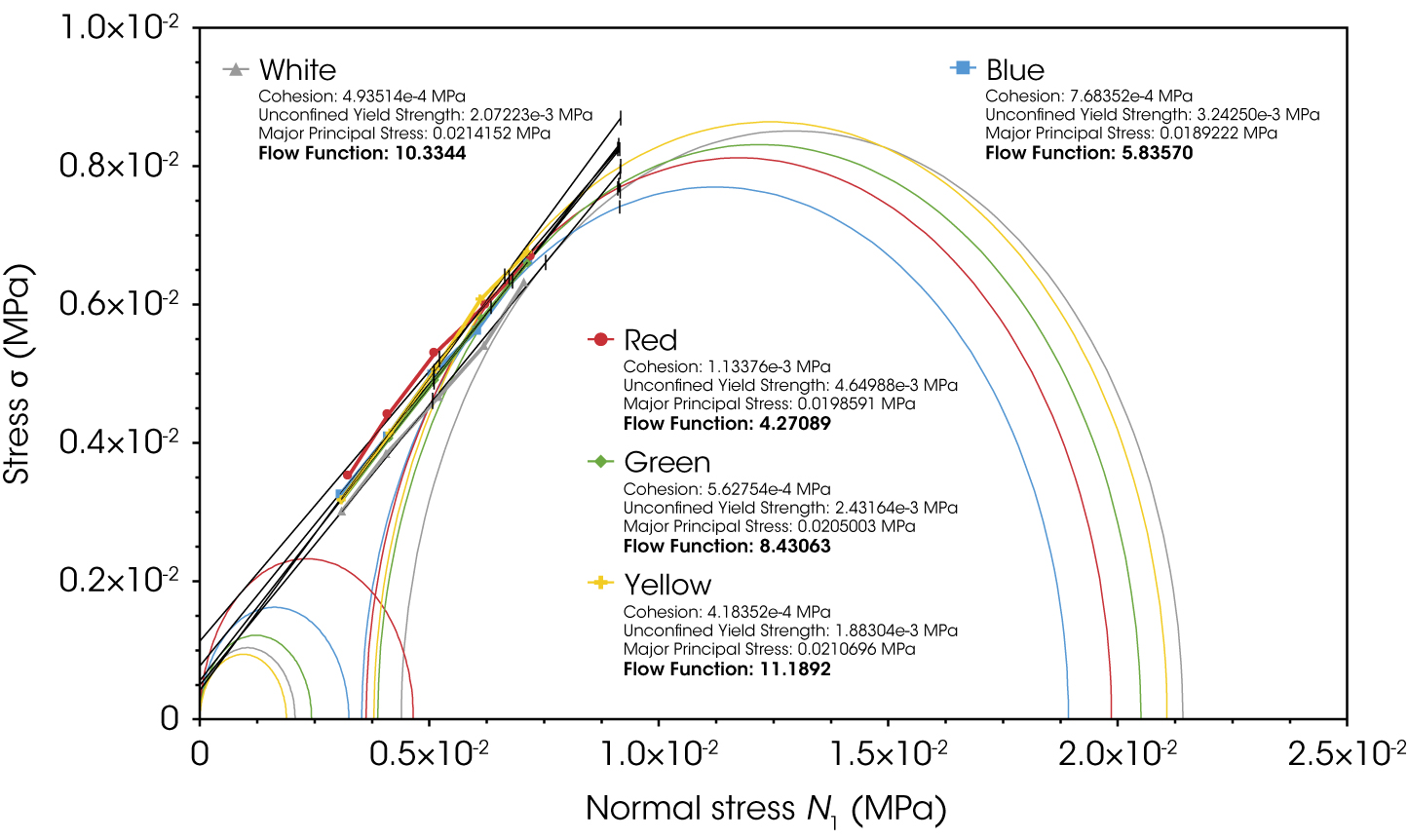

Next, we measured the flow function of these powders (See Fig. 2). The flow function reveals how easily a powder can flow and be processed under relatively high stress. Here’s what we discovered:

- White and yellow Powders: These powders are right on the edge of easy and free-flowing. They will flow smoothly from the squeeze bottle without any hiccups.

- Blue and Red Powders: These powders are a bit more stubborn. Their flow function is on the border of easy-flowing and cohesive flow, meaning they’ll have a tougher time flowing from the squeeze bottle.

We also looked at the unconfined yield strength of these powders. This tells us how well the powders can resist forces like the wind. The blue and red powders showed twice the yield strength of the white and yellow ones. So, if you’re working on your rangoli outside in a windy area and pressing your powders down onto your design, the blue and red ones will hold their ground better.

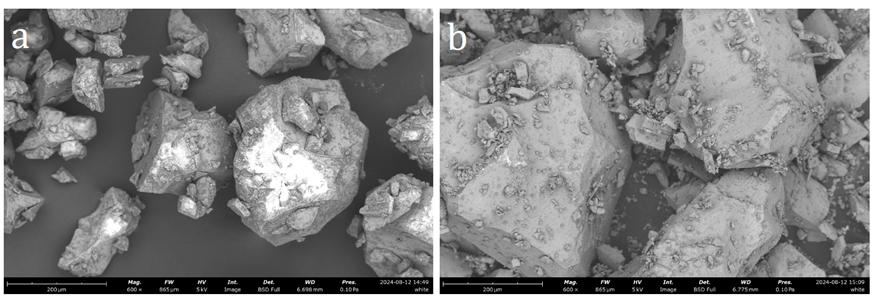

From our SEM images (Fig. 3), we saw that coloring process with pigments not only altered the appearance of the blue powder but also modified its physical properties. The blue powder is made up of smaller particles than the white and has smoother, rounder surfaces. This change wasn’t just cosmetic—these tiny particles, with higher surface area to volume ratio, significantly boosted the blue powder’s compressibility and cohesion, which we saw earlier in Figures 1 and 2. It’s amazing how a bit of pigment, some shaking, and drying can dramatically change the rheology of a powder!

In summary, our curiosity about the rheology of rangoli powders revealed some cool insights into how rangoli powders behave under distinct flow conditions. Whether you’re looking for easy flow or better resistance to wind, now you know which powders to pick.

The Curious Case of Turmeric and Green Powder: A Rangoli Revelation

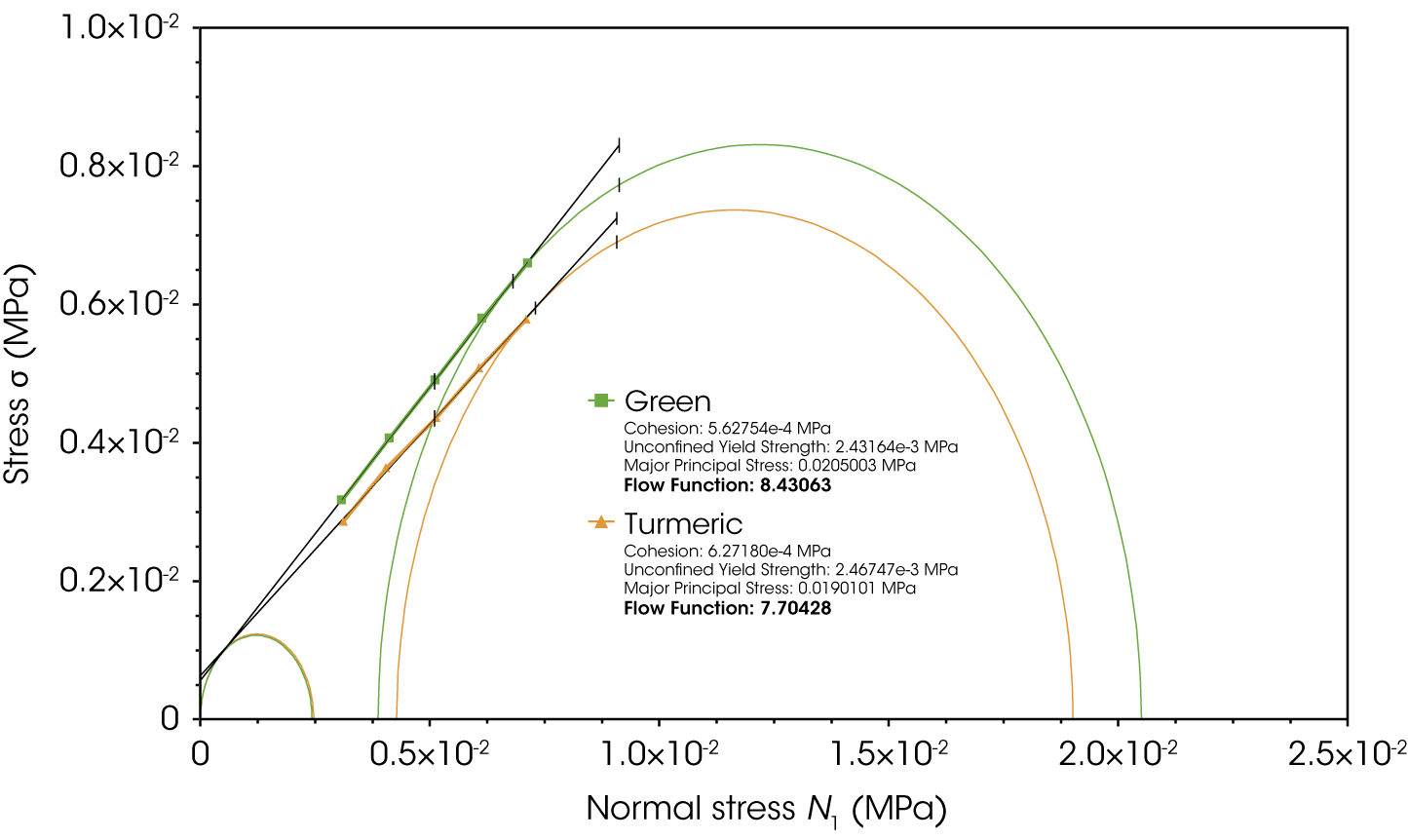

Sometimes, very different powders can surprise us with similar traits. Take turmeric, for example – a popular choice for rangoli. Despite looking finer and lighter than the rangoli powders we used, turmeric interestingly shares the same flow function value as the green powder (See Fig. 4).

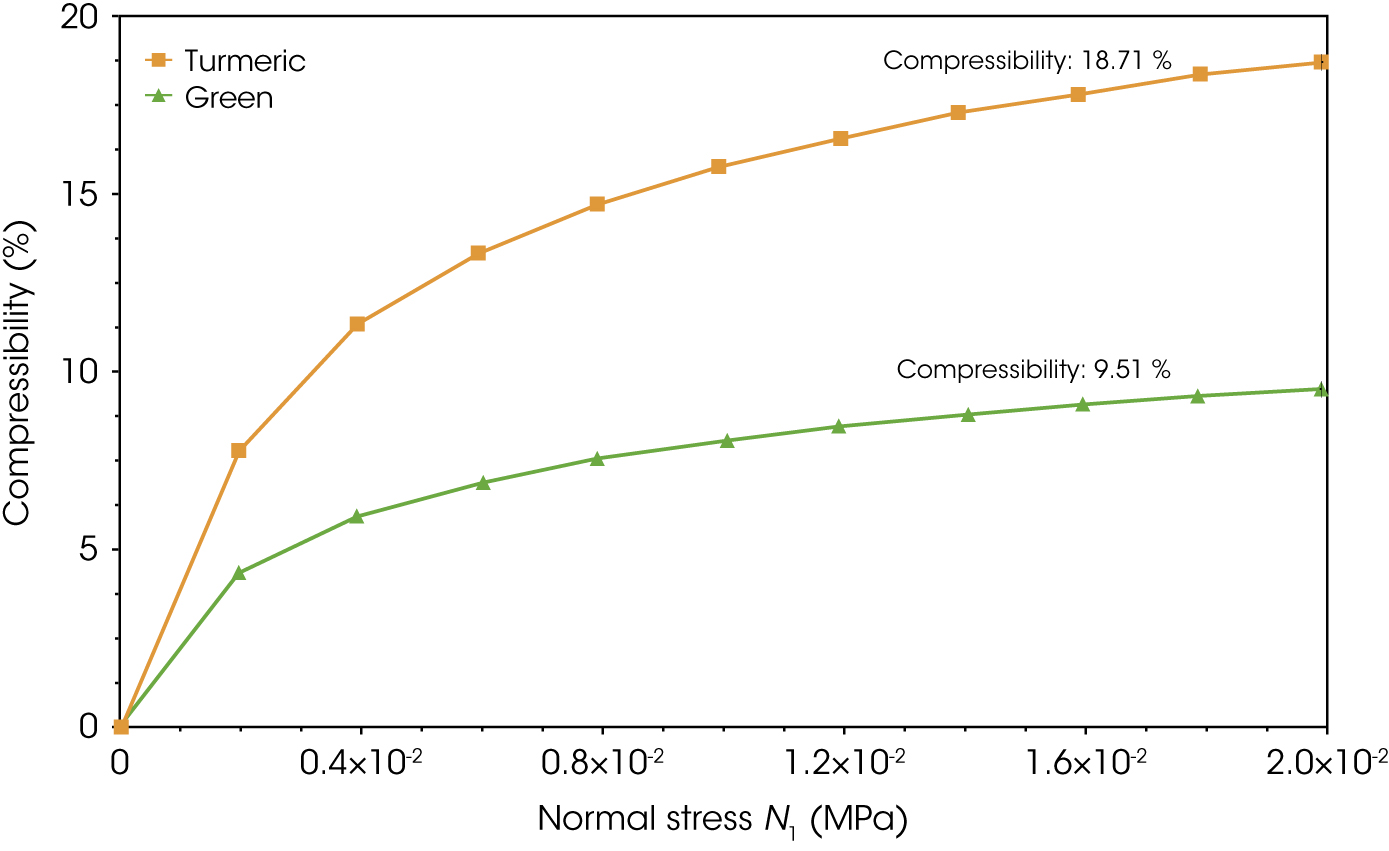

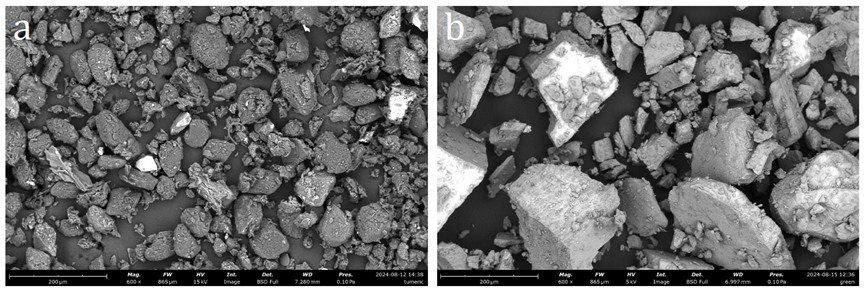

Why, you ask? Well, turmeric can be compressed twice as much as the green powder (see Fig. 5), likely boosting its cohesion under higher stress. When we examined the powders using SEM (see Fig. 6), we noticed that both powders had a lot of small debris, which can affect their cohesion and flowability when compacted.

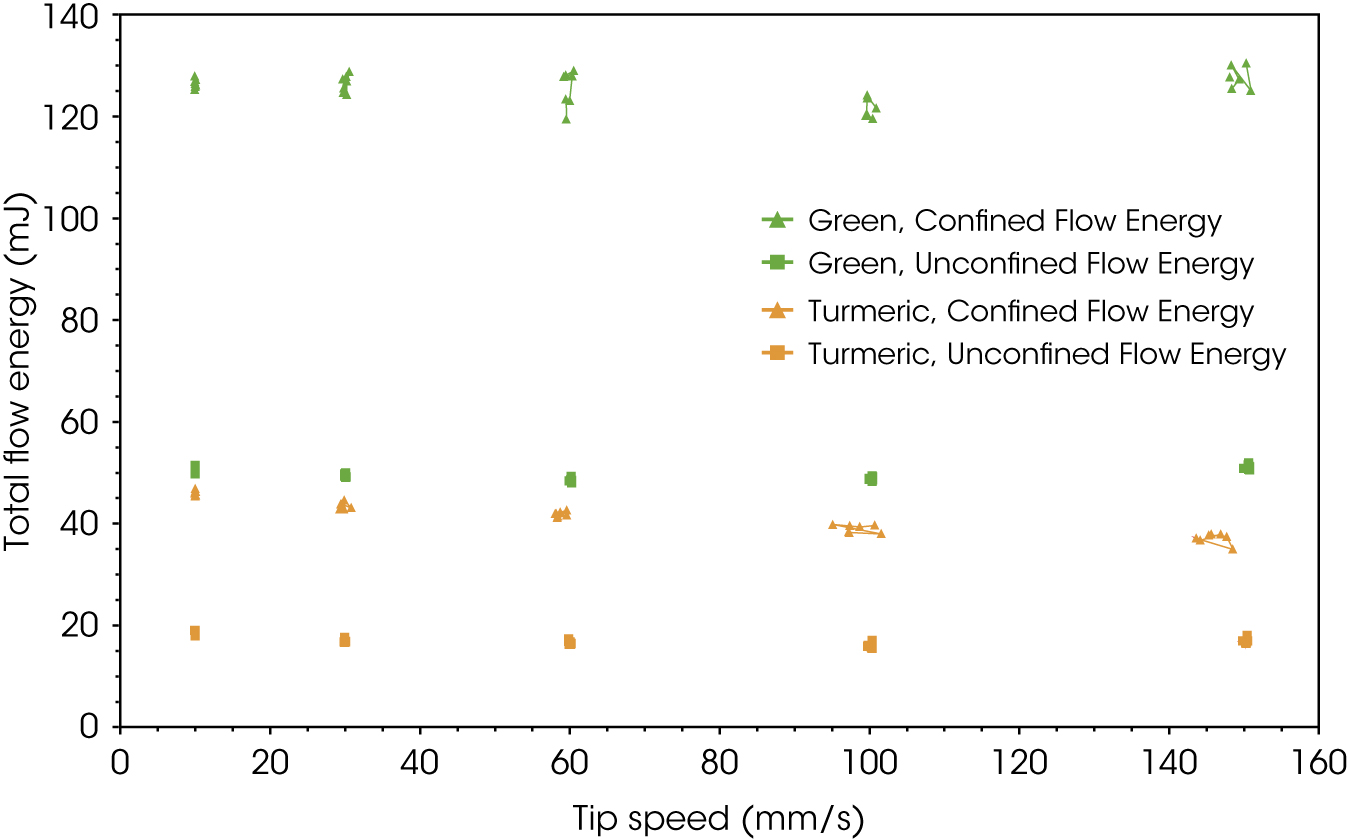

However, when it comes to unconfined and confined flow energy—where the powders aren’t under high stress – the green powder’s flow energy is significantly higher than turmeric’s (See Fig. 7). This could be due to several factors, including the rounder surface of turmeric compared to the rougher surface of the green powder.

So, while turmeric and green powder may look and feel different, they can behave quite similarly under certain conditions. When you flow these two powders from a squeeze bottle, you experience the same flowability. However, when you spread them on the surface to create designs with your brush or finger, turmeric flows much more easily. It’s a fascinating reminder that appearances can be deceiving, especially in the world of powders!

As we dive into the festive spirit of Diwali, the art of rangoli brings a playful twist to powder rheology. Whether it’s the smooth flow of white powder or the stubbornness of blue powder, each has its unique charm and challenges.

However, in industrial settings, these properties are more than just fascinating – they’re critical. So, whether you’re spreading turmeric for a beautiful rangoli or ensuring the consistency of a pharmaceutical product, understanding powder rheology is key. It’s a fascinating blend of art and science that keeps both our celebrations and industries running smoothly.

Other Resources

- Application Note – Epoxy Powder Rheology: Impact of Temperature on Flow and Shear Properties

- Application Note – Effect of Moisture and Substrate Material on Wall Friction Angle of Carboxymethyl Cellulose Powder

- Application Note – Effect of Moisture on Cohesion Strength of Carboxymethyl Cellulose Powder

- Application Note – Powder Rheology of Graphite: Characterization of Natural and Synthetic Graphite for Battery Anode Slurries

- Blog – Powder Rheology for Pharmaceutical Development

- Accessory – Powder Rheology

- Contact – Contact TA Instruments Today