Cell (SPC)

Starch Pasting Cell (SPC)

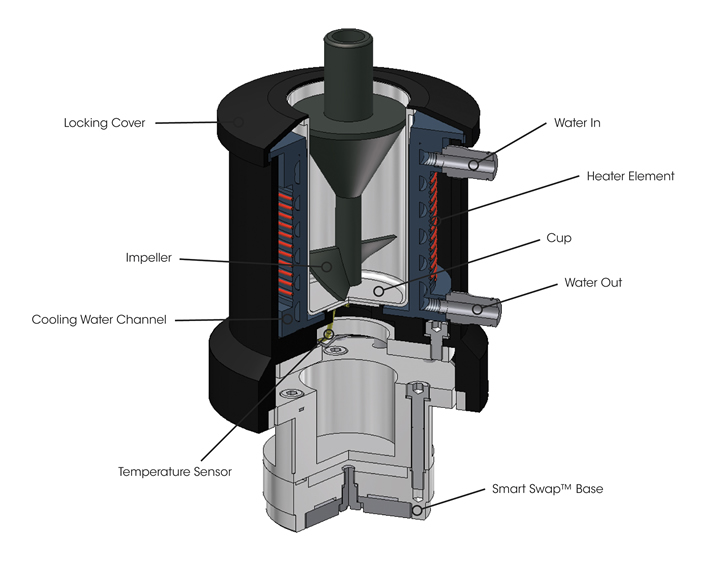

The Starch Pasting Cell (SPC) provides a more accurate and powerful tool to characterize the gelatinization of raw and modified starch products, as well as the properties of the starch gels. It can also be used for characterizing many other highly unstable materials. It uses an innovative impeller design for mixing, reduction of water loss, and control of sedimentation during testing. The actual sample temperature is measured and controlled in a temperature chamber with heating/cooling rates up to 30 °C/min.

Technology

The SPC consists of the cell jacket, an impeller, and aluminum cup with locking cover. The cell jacket houses a heating coil and liquid cooling channel, which surrounds the Aluminum cup for fast heating and cooling. A Platinum Resistance Thermometer (PRT) is located in intimate contact with the bottom of the cup for precise and accurate sample temperature control. The impeller is designed with blades at the bottom for sample mixing. Solvent loss is minimized via a conical ring at the top of the rotor, which acts to condense water (or other solvents) that vaporizes during heating, and return it to the bulk sample.

Features and Benefits

- Smart Swap™ technology

- Heating/Cooling rates up 30 °C/min

- Higher accuracy for greater reproducibility

- Robust Cup and Impeller

- Impeller keeps unstable particles suspended in liquid phase during measurements

- Impeller design minimizes loss of water or other solvents

- Sample temperature measured directly

- All rheometer test modes available for advanced measurements on gelled starches and other materials

- Optional conical rotor for traditional rheological measurements

Gelatinization of Starch Products

Gelatinization of Starch Products

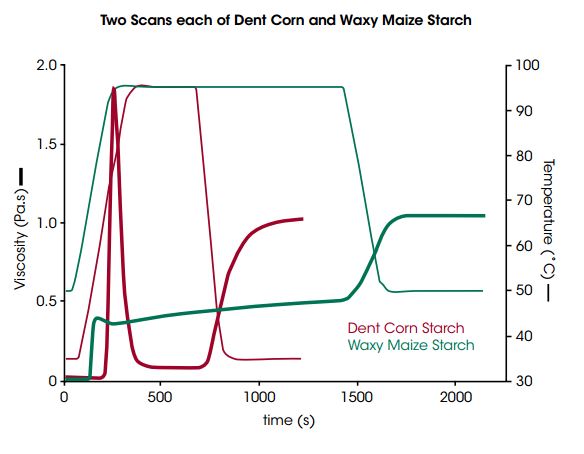

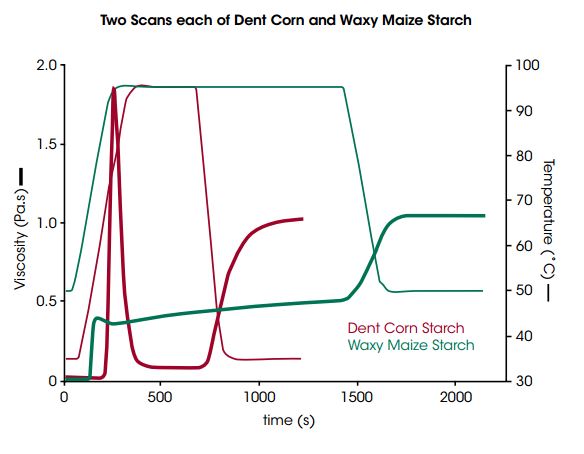

Starch is not only a food product; functionally modified starches are widely used in the industry including adhesives, paper, coatings, wood, packaging, pharmaceutical, and many others. When starch is heated above a critical temperature, the starch granules undergo an irreversible process, known as gelatinization. The properties of the starch gels depend on the origin of the raw starch (crop, potatoes, etc.), the environmental conditions (seasons) or the modification. The viscosity curve, referred to as pasting curve, produced by heating and cooling starches generally has a similar characteristic shape.

The figure above shows two scans each of both a Dent Corn and Waxy Maize starch. The benefit of the DHR starch cell design can easily be observed in the unprecedented reproducibility of the pasting curves for these two starch products..

Advanced Starch Rheology

Advanced Starch Rheology

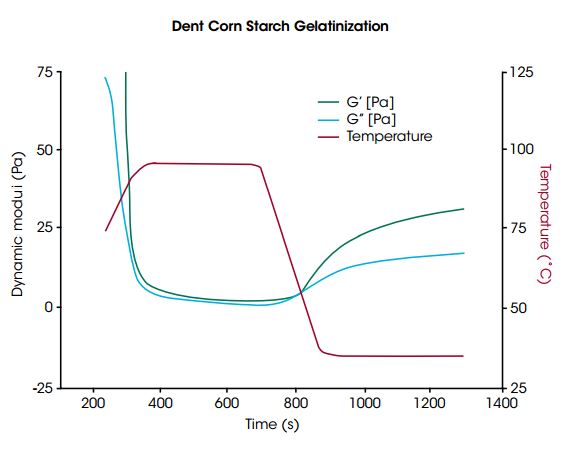

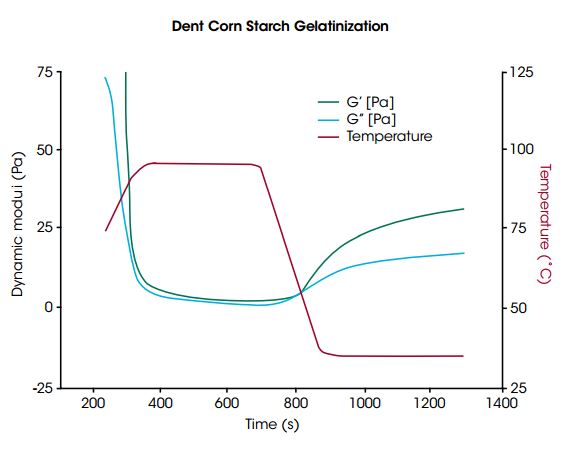

In addition to measuring the characteristic pasting curve of starch products, the starch cell brings new testing capabilities for measuring properties of the starch gels. The figure to the right shows additional data obtained on Dent Corn starch using an oscillation test to monitor the gelation process of the starch under negligible shearing. In this test, the sample is sheared while ramping temperature to keep starch particles suspended. At 75 °C, when the viscosity is high enough to inhibit particle settling, the steady shear was stopped and testing was continued at a small oscillating stress. The figure shows storage modulus, G’, and the loss modulus, G”. which provide extremely sensitive information about the structural characteristics of the starch gelation and final gel. This enables the development of valuable structure-property relationships. The ability to make these sensitive measurements is not possible on traditional starch characterization instrumentation.

- Description

-

Starch Pasting Cell (SPC)

The Starch Pasting Cell (SPC) provides a more accurate and powerful tool to characterize the gelatinization of raw and modified starch products, as well as the properties of the starch gels. It can also be used for characterizing many other highly unstable materials. It uses an innovative impeller design for mixing, reduction of water loss, and control of sedimentation during testing. The actual sample temperature is measured and controlled in a temperature chamber with heating/cooling rates up to 30 °C/min.

- Technology

-

Technology

The SPC consists of the cell jacket, an impeller, and aluminum cup with locking cover. The cell jacket houses a heating coil and liquid cooling channel, which surrounds the Aluminum cup for fast heating and cooling. A Platinum Resistance Thermometer (PRT) is located in intimate contact with the bottom of the cup for precise and accurate sample temperature control. The impeller is designed with blades at the bottom for sample mixing. Solvent loss is minimized via a conical ring at the top of the rotor, which acts to condense water (or other solvents) that vaporizes during heating, and return it to the bulk sample.

- Features

-

Features and Benefits

- Smart Swap™ technology

- Heating/Cooling rates up 30 °C/min

- Higher accuracy for greater reproducibility

- Robust Cup and Impeller

- Impeller keeps unstable particles suspended in liquid phase during measurements

- Impeller design minimizes loss of water or other solvents

- Sample temperature measured directly

- All rheometer test modes available for advanced measurements on gelled starches and other materials

- Optional conical rotor for traditional rheological measurements

- Applications

-

Gelatinization of Starch Products

Gelatinization of Starch Products

Starch is not only a food product; functionally modified starches are widely used in the industry including adhesives, paper, coatings, wood, packaging, pharmaceutical, and many others. When starch is heated above a critical temperature, the starch granules undergo an irreversible process, known as gelatinization. The properties of the starch gels depend on the origin of the raw starch (crop, potatoes, etc.), the environmental conditions (seasons) or the modification. The viscosity curve, referred to as pasting curve, produced by heating and cooling starches generally has a similar characteristic shape.

The figure above shows two scans each of both a Dent Corn and Waxy Maize starch. The benefit of the DHR starch cell design can easily be observed in the unprecedented reproducibility of the pasting curves for these two starch products..

Advanced Starch Rheology

Advanced Starch Rheology

In addition to measuring the characteristic pasting curve of starch products, the starch cell brings new testing capabilities for measuring properties of the starch gels. The figure to the right shows additional data obtained on Dent Corn starch using an oscillation test to monitor the gelation process of the starch under negligible shearing. In this test, the sample is sheared while ramping temperature to keep starch particles suspended. At 75 °C, when the viscosity is high enough to inhibit particle settling, the steady shear was stopped and testing was continued at a small oscillating stress. The figure shows storage modulus, G’, and the loss modulus, G”. which provide extremely sensitive information about the structural characteristics of the starch gelation and final gel. This enables the development of valuable structure-property relationships. The ability to make these sensitive measurements is not possible on traditional starch characterization instrumentation.