The Importance of Reliable Mixing in ITC Experiments

Morgan Ulrich | Calliste Scholl

April 24, 2025

ITC is the most sensitive method for characterizing binding interactions, revealing critical attributes like drug efficacy and stability. But without proper mixing, ITC data is unreliable and unusable. Great ITC experiments start with correct mixing.

Characterizing binding events is critical for understanding any physiological processes at the molecular level. Modern biochemical and biomedical research relies on precisely analyzing binding reactions with Isothermal titration calorimetry (ITC), the most accurate, sensitive method for analyzing molecular interactions.

ITC involves mixing the titrant into the titrand and measuring the heat released or absorbed during the binding reaction, providing critical thermodynamic data to characterize complex processes without altering samples‘ structure or composition. Since ITC experiments measure that reaction as the samples are mixed, the ultimate accuracy and reliability of ITC data hinges upon proper mixing.

Why is mixing important in ITC experiments?

Ensures Homogeneity

Proper mixing during an ITC experiment ensures a uniform distribution of reactants throughout the sample cells. This uniformity is essential for accurately measuring the interactions of all reactants by ITC.

Without homogeneity, samples can have localized concentration gradients, meaning the titrants have zones of high and low concentrations. This disparity can distort thermodynamic readings, leading to incorrect ITC interpretations of binding affinities and reaction kinetics.

Enhances Reaction Kinetics

With titrants accurately mixed throughout the sample, experiments can have faster and more complete reactions. These experiments have improved data quality and reliability, as ITC is able to accurately characterize binding as it would happen in application.

Common Errors and Consequences of Poor Mixing in ITC Experiments

Poorly mixed ITC experiments have a high likelihood of giving inaccurate or unusable results. Mixing that is too slow or inefficient can lead to split peaks, causing errors in analysis and data interpretation. Conversely, too high of a stir rate can damage samples; operators may not know about this damage and report incorrect values as a result.

How TA Instruments Optimize ITC Mixing

With numerous potential pitfalls and problems, choosing an Isothermal Titration Calorimeter that is designed to simplify mixing can save countless hours of failed experiments and lost data. With decades of successful innovation and solving customer challenges, we designed the Affinity ITC to give the highest confidence and superior data.

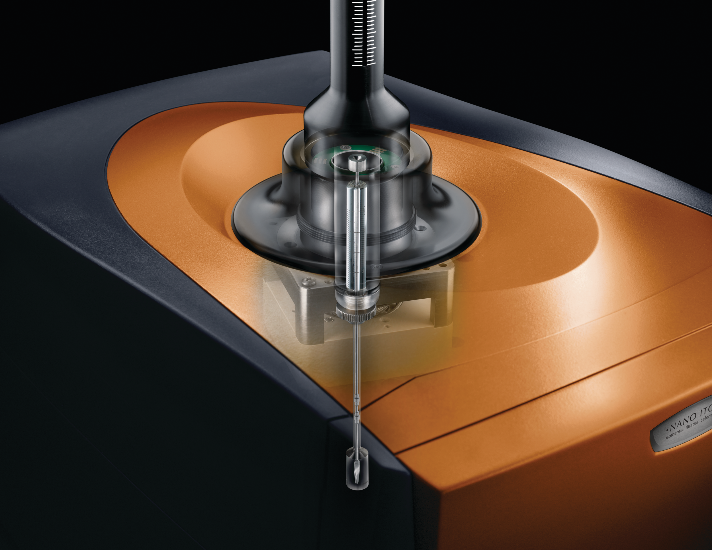

Cell Design

The Affinity ITC’s cylindrical cell minimizes the distance a ligand must travel to reach its binding target. This design promotes more efficient mixing while eliminating dead zones and entrapped air bubbles which are common in competitive designs.

Stir Paddle

The Affinity ITC’s revolutionary FlexSpin™ paddle is thin and twisted, allowing for the most efficient mixing on the market at ultra-low stir rates. The Affinity ITC stirs ten times slower than other ITC on the market, offering the highest sensitivity while protecting delicate structures. In conjunction with the cylindrical cell shape, the stir paddle eliminates dead zones. The revolutionary FlexSpin™ paddle is optimized for better mixing, sharper peaks, and faster equilibration times.

The Affinity ITC’s revolutionary FlexSpin™ paddle is thin and twisted, allowing for the most efficient mixing on the market at ultra-low stir rates. The Affinity ITC stirs ten times slower than other ITC on the market, offering the highest sensitivity while protecting delicate structures. In conjunction with the cylindrical cell shape, the stir paddle eliminates dead zones. The revolutionary FlexSpin™ paddle is optimized for better mixing, sharper peaks, and faster equilibration times.

Injection Location

Finally, the Affinity ITC uniquely positions the syringe needle to deliver the titrant at the top of the stirring paddle for immediate, efficient mixing. Other calorimeters inject the titrant from the bottom, so it must travel upwards to reach the paddle and be mixed. The ability of the titrant to reach its target more efficiently results in sharper peaks and faster return to baseline.

A Complete ITC Mixing Solution

The Affinity ITC has optimized mixing with its innovative cylindrical cell, FlexSpin™ stir paddle, and top injection location. Together, these three features allow the Affinity ITC to mix at average stir rates of 125 RPM – significantly lower than other instruments on the market. And the Affinity ITC’s technology reduces peak width by up to 50%, delivering ITC data users can easily interpret and trust. Although mixing can seem complicated, the Affinity ITC is built to simplify mixing and streamline testing for reliable results.

The Affinity ITC has optimized mixing with its innovative cylindrical cell, FlexSpin™ stir paddle, and top injection location. Together, these three features allow the Affinity ITC to mix at average stir rates of 125 RPM – significantly lower than other instruments on the market. And the Affinity ITC’s technology reduces peak width by up to 50%, delivering ITC data users can easily interpret and trust. Although mixing can seem complicated, the Affinity ITC is built to simplify mixing and streamline testing for reliable results.

Learn more about the Affinity ITC and contact TA Instruments‘ experts to explore the right solutions for your testing success.

Other Resources

- Blog – Isothermal Titration Calorimetry (ITC) for Binding Characterization in Pharmaceutical Research

- Blog – How to Assess Binding in Drug Discovery

- Application Note – Characterizing Binding Interactions by ITC

- Instrument – Isothermal Titration Calorimeters

- Webinar – Elucidating Thermodynamic Details of Biologic and Small Molecule Drugs using Microcalorimetry