Measure friction and wear between two solid surfaces under dry or lubricated conditions.

The new Tribo-Rheometry Accessory enables the measurement of friction and wear directly under the widest range of industrial conditions. This system employs a modular set of standard and novel geometries to add entirely new capability to the ARES-G2 rotational shear rheometer. The coefficient of friction of two solid surfaces in contact can be measured under multiple dry and lubricated conditions and contact profiles. An innovative new self-aligning design ensures uniform solid-solid contact in an easy-to-use and quick-to-install accessory. Tribology experiments also benefit from the preeminent speed control of the ARES-G2, separate torque measurement, and the unrivaled normal force accuracy and stability of the Force Rebalance Transducer.

Experiments are controlled and results are calculated directly through the advanced TRIOS software. Measured quantities include the coefficient of friction (μ), load force (FL), friction force (FF) and Gumbel number (Gu). These may be used to construct Stribeck curves, static friction measurements, or explore specific combinations of temperature, contact force, and motion.

Features and Benefits:

- Compatible with Advanced Peltier System (APS) and Forced Convection Oven (FCO)

- Characterize materials wear and coefficient of friction under dry or lubricated conditions

- Unique self-aligning design for best solid-solid contact

- Modular set of geometries offers choice of contact profiles

- Interchangeable parts for customized substrates

- Automatic software calculation of relevant friction parameters

- Easy installation and removal

| Temperature Range | Max Load Force | Max Sliding Speed | ||

| APS | FCO | |||

| Ring on Plate | -10oC to 150oC | -150oC to 180oC | 20N | 4.5m/s |

| Ball on Three Plates | -10oC to 150oC | -150oC to 350oC | 28N | 2.7m/s |

| Ball on Three Balls | -10oC to 150oC | -150oC to 350oC | 24N | 2.3m/s |

| Three Balls on Plate | -10oC to 150oC | -150oC to 180oC | 20N | 4.5m/s |

-10oC to 150oC

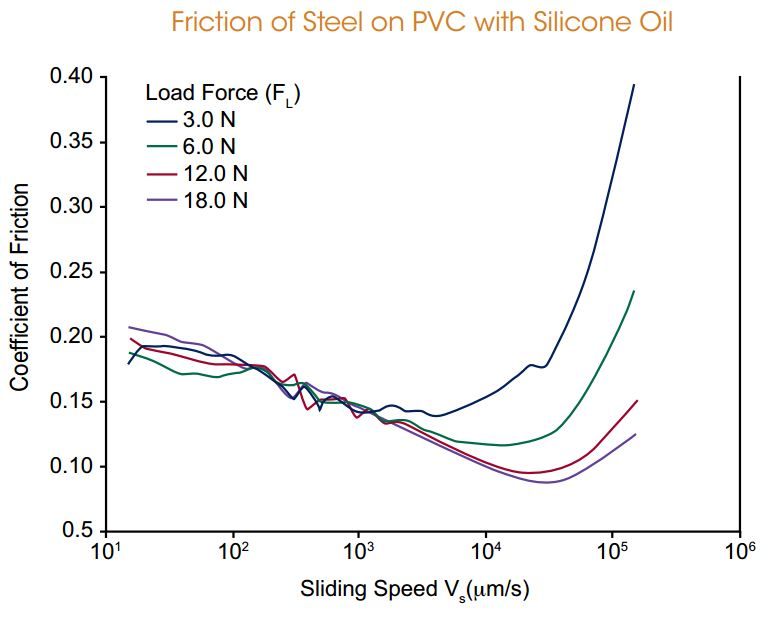

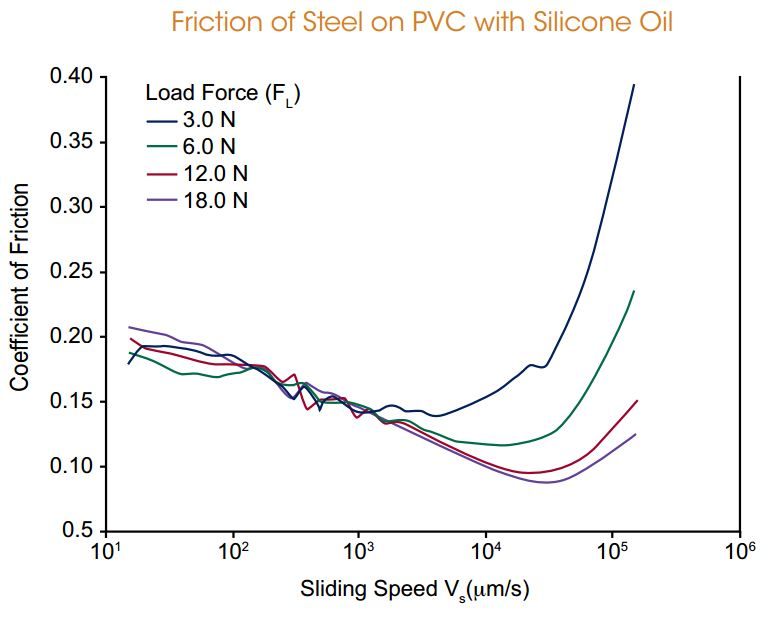

Stainless Steel Ring on PVC Plate: The accompanying figure shows the coefficient of friction between a Stainless Steel ring and a PVC plate lubricated by silicone oil. As the sliding speed between the surfaces is increased, the coefficient of friction initially decreases before systematically increasing with a marked dependence on the axial load. The initial decrease reflects the lubrication of the surface by the silicone oil; increased friction at higher speeds suggests a crossover into the hydrodynamic region of the Stribeck curve where frictional effects are dominated by fluid drag.

- Description

-

The new Tribo-Rheometry Accessory enables the measurement of friction and wear directly under the widest range of industrial conditions. This system employs a modular set of standard and novel geometries to add entirely new capability to the ARES-G2 rotational shear rheometer. The coefficient of friction of two solid surfaces in contact can be measured under multiple dry and lubricated conditions and contact profiles. An innovative new self-aligning design ensures uniform solid-solid contact in an easy-to-use and quick-to-install accessory. Tribology experiments also benefit from the preeminent speed control of the ARES-G2, separate torque measurement, and the unrivaled normal force accuracy and stability of the Force Rebalance Transducer.

Experiments are controlled and results are calculated directly through the advanced TRIOS software. Measured quantities include the coefficient of friction (μ), load force (FL), friction force (FF) and Gumbel number (Gu). These may be used to construct Stribeck curves, static friction measurements, or explore specific combinations of temperature, contact force, and motion.

- Features

-

Features and Benefits:

- Compatible with Advanced Peltier System (APS) and Forced Convection Oven (FCO)

- Characterize materials wear and coefficient of friction under dry or lubricated conditions

- Unique self-aligning design for best solid-solid contact

- Modular set of geometries offers choice of contact profiles

- Interchangeable parts for customized substrates

- Automatic software calculation of relevant friction parameters

- Easy installation and removal

- Specifications

-

Temperature Range Max Load Force Max Sliding Speed APS FCO Ring on Plate -10oC to 150oC -150oC to 180oC 20N 4.5m/s Ball on Three Plates -10oC to 150oC -150oC to 350oC 28N 2.7m/s Ball on Three Balls -10oC to 150oC -150oC to 350oC 24N 2.3m/s Three Balls on Plate -10oC to 150oC -150oC to 180oC 20N 4.5m/s -10oC to 150oC

- Applications

-

Stainless Steel Ring on PVC Plate: The accompanying figure shows the coefficient of friction between a Stainless Steel ring and a PVC plate lubricated by silicone oil. As the sliding speed between the surfaces is increased, the coefficient of friction initially decreases before systematically increasing with a marked dependence on the axial load. The initial decrease reflects the lubrication of the surface by the silicone oil; increased friction at higher speeds suggests a crossover into the hydrodynamic region of the Stribeck curve where frictional effects are dominated by fluid drag.