Designed for use with Peltier plates to eliminate vertical temperature gradients in samples.

Upper Heated Plate For Peltier Plate (UHP)

Technology

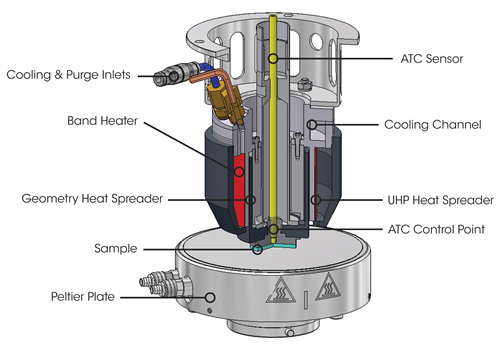

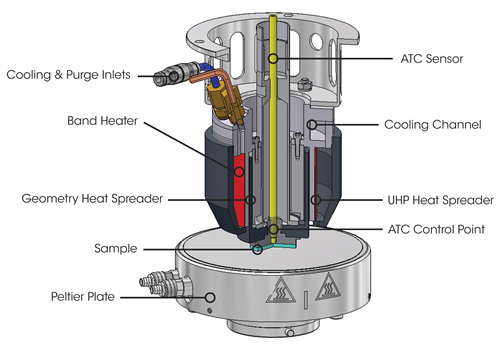

The UHP sets a new standard in non-contact heating with patented technologies that deliver the most accurate and reliable temperature control. A cylindrical heat transfer unit, with an integrated electric heater and a liquid/gas cooling channel, surrounds the cylindrical heat spreader geometry.

These two components are in very close proximity, but do not contact, enabling efficient heat transfer and unimpeded torque measurement. Unlike competitive designs, the heat transfer unit and the geometry heat spreader remain in constant spatial relation to one another regardless of the test gap, keeping heat transfer uniform at all times.

A unique calibration permits the system to match upper and lower plate temperatures at all heating rates, ensuring uniform sample heating on both sides, virtually eliminating the need for thermal equilibrium time and enabling true temperature ramp experiments. Conventional, non-contact upper heaters require an offset calibration between the directly measured heater temperature and the indirectly calibrated plate temperature. Patented Active Temperature Control (ATC) eliminates the need for a heaterto-plate offset table by directly measuring the upper plate temperature at all times. See ATC technology section for more details.

Active Temperature Control Technology (ATC)

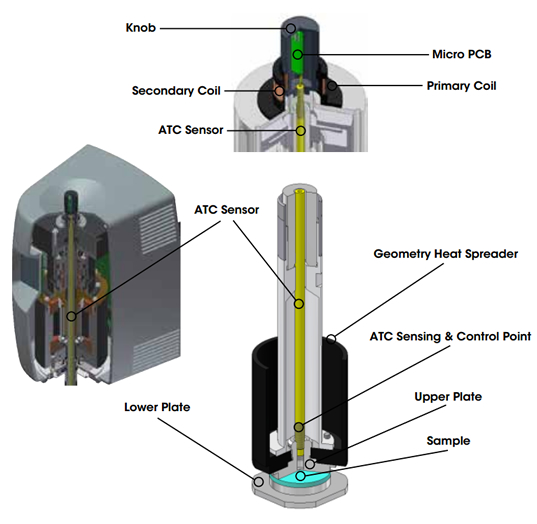

Patented Active Temperature Control (ATC) provides non-contact temperature sensing for active measurement and control of the upper testing surface. A Platinum Resistance Thermometer (PRT) is housed within the special ATC draw rod. This PRT is positioned in intimate contact with the center of the upper measurement surface. The temperature signal is transmitted to a micro PCB in the knob, from which the temperature reading is transmitted through a non-contact mechanism to the rheometer head assembly. This temperature reading enables direct control of the actual upper plate temperature. Because the upper plate temperature is measured and controlled directly, the system has many advantages over traditional systems. The advantages of ATC include: more responsive temperature control, no vertical temperature gradients, and no need for inferring actual temperature from complex calibration procedures and offset tables. Together with the PRT in the lower plate, real-time control of both plates allows temperature to be changed at both surfaces at the same rate for true temperature ramp profiles. NOTE: Active Temperature Control (ATC) is available for Upper Heated Plate (UHP) and Electrically Heated Plate (EHP) temperature systems.

Features and Benefits

- Smart Swap™ technology

- Wide temperature range: -30 °C* to 150 °C

- Eliminates vertical temperature gradients

- Patented heat spreader technology for optimum heat transfer

- Substantially reduces thermal equilibrium time

- Compatible with all Peltier Plate models

- Patented Active Temperature Control** for significant temperature control advantages: –

- Only active temperature measurement and control of non-contact heating system available

- Temperature known rather than inferred

- No need for offset calibrations and tables

- True temperature ramp capability up to 15 °C per minute

- Faster temperature response compared to traditional non-contact systems

- Includes sample trimming and plate removal tools

- Gas purge port and environment cover

- Disposable Plate system available for reactive systems

- Compatible with Peltier liquid cooling, circulator, or gas cooling options

*With appropriate cooling device

**Not available with disposable plates

- Description

-

Upper Heated Plate For Peltier Plate (UHP)

The UHP is a temperature option designed for use with Peltier plates to eliminate vertical temperature gradients in samples. These thermal gradients can become significant above 50 °C and lead to errors in absolute rheological data. The UHP is the most advanced non-contact heating system available, using patented heat spreader technology (1) to deliver maximum heat transfer efficiency and patented active temperature control (2) for direct measurement and control of the upper plate temperature. The UHP has a maximum operating temperature of 150 °C and the lower temperature can be extended using liquid or gas cooling options. (Note: To extend the upper heated temperature range to 200 °C, see electrically heated plates option).(1) U.S. Patent # 7,168,299(2) U.S. Patent # 6,931,915 - Technology

-

Technology

The UHP sets a new standard in non-contact heating with patented technologies that deliver the most accurate and reliable temperature control. A cylindrical heat transfer unit, with an integrated electric heater and a liquid/gas cooling channel, surrounds the cylindrical heat spreader geometry.

These two components are in very close proximity, but do not contact, enabling efficient heat transfer and unimpeded torque measurement. Unlike competitive designs, the heat transfer unit and the geometry heat spreader remain in constant spatial relation to one another regardless of the test gap, keeping heat transfer uniform at all times.

A unique calibration permits the system to match upper and lower plate temperatures at all heating rates, ensuring uniform sample heating on both sides, virtually eliminating the need for thermal equilibrium time and enabling true temperature ramp experiments. Conventional, non-contact upper heaters require an offset calibration between the directly measured heater temperature and the indirectly calibrated plate temperature. Patented Active Temperature Control (ATC) eliminates the need for a heaterto-plate offset table by directly measuring the upper plate temperature at all times. See ATC technology section for more details.

Active Temperature Control Technology (ATC)

Patented Active Temperature Control (ATC) provides non-contact temperature sensing for active measurement and control of the upper testing surface. A Platinum Resistance Thermometer (PRT) is housed within the special ATC draw rod. This PRT is positioned in intimate contact with the center of the upper measurement surface. The temperature signal is transmitted to a micro PCB in the knob, from which the temperature reading is transmitted through a non-contact mechanism to the rheometer head assembly. This temperature reading enables direct control of the actual upper plate temperature. Because the upper plate temperature is measured and controlled directly, the system has many advantages over traditional systems. The advantages of ATC include: more responsive temperature control, no vertical temperature gradients, and no need for inferring actual temperature from complex calibration procedures and offset tables. Together with the PRT in the lower plate, real-time control of both plates allows temperature to be changed at both surfaces at the same rate for true temperature ramp profiles. NOTE: Active Temperature Control (ATC) is available for Upper Heated Plate (UHP) and Electrically Heated Plate (EHP) temperature systems.

- Features

-

Features and Benefits

- Smart Swap™ technology

- Wide temperature range: -30 °C* to 150 °C

- Eliminates vertical temperature gradients

- Patented heat spreader technology for optimum heat transfer

- Substantially reduces thermal equilibrium time

- Compatible with all Peltier Plate models

- Patented Active Temperature Control** for significant temperature control advantages: –

- Only active temperature measurement and control of non-contact heating system available

- Temperature known rather than inferred

- No need for offset calibrations and tables

- True temperature ramp capability up to 15 °C per minute

- Faster temperature response compared to traditional non-contact systems

- Includes sample trimming and plate removal tools

- Gas purge port and environment cover

- Disposable Plate system available for reactive systems

- Compatible with Peltier liquid cooling, circulator, or gas cooling options

*With appropriate cooling device

**Not available with disposable plates