Fast-responding temperature control and unmatched accuracy when testing away from ambient.

Upper Peltier Plate For Peltier Plate (UPP)

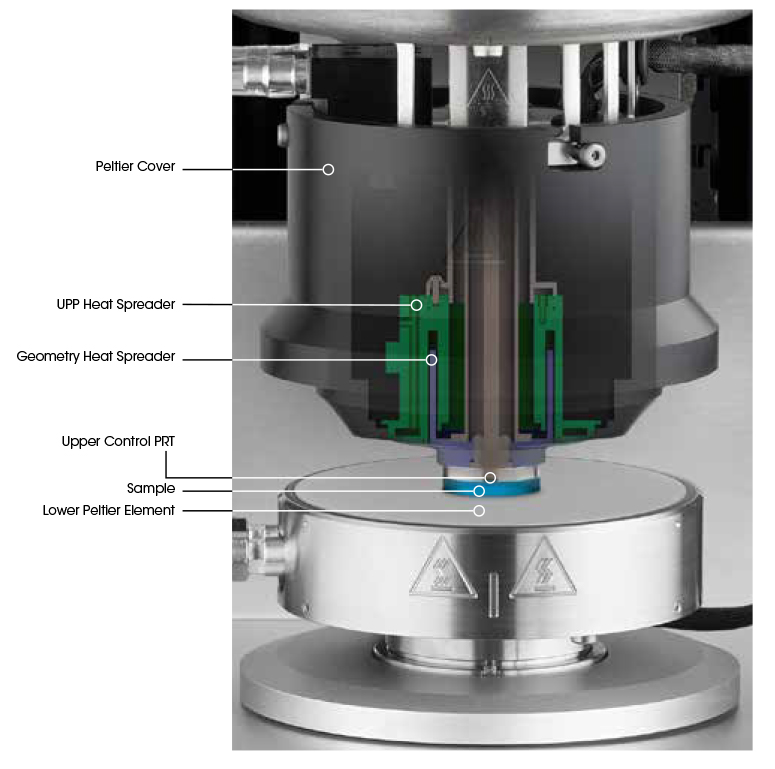

The UPP is a fast-responding temperature control system vital when testing at temperatures away from ambient. Measurement errors upwards of 40% can occur when limiting temperature control to one side of the sample, even at 40 °C, and only grow when moving further from ambient. Using the UPP in conjunction with lower Peltier plates delivers uniform and precise temperature control from -40 °C to 200 °C, eliminating measurement errors in viscosity, yield stress, G’, G”, tan δ, and other rheological data.

The UPP is the only Peltier-based upper heater technology with direct temperature measurements at the sample, made possible through TA’s patented active temperature control (ATC)1. This technology combines with TA’s patented heat spreader technology2 to drive heat directly to the sample for the most accurate temperature control and material characterization, meeting a wide range of testing needs.

Features and Benefits

- Patented heat spreader conducts heat directly to sample, creating a uniform sample temperature and eliminating measurement errors

- Fast-responding temperature control driven by Peltier elements for improved productivity

- Wide operating temperature range from -40 °C to 200 °C* in a simple and compact configuration without liquid nitrogen or mechanical chillers

- Direct sample temperature measurement with patented ATC delivers unmatched data reproducibility with oven systems (ETC and FCO)

- Protect samples from environmental influences:

- Solvent reservoir option: prevents evaporation for aqueous and volatile samples

- Thermal shield: protects from moisture condensation

- Gas purge ports: prevent degradation with inert atmosphere

- Compatible with additional accessories to meet every testing need:

- All Peltier plates, including disposable and screw-in plates

- UV curing accessories

- Modular microscope (MMA)

- Optics plate accessory (OPA)

* Testing up to 200 °C requires HT-APP with the UPP

Technology

The UPP’s innovative Peltier-element design maximizes the speed of temperature response and delivers access to sub-ambient temperatures without liquid nitrogen or expensive fluid circulator setups. Whether programming temperature steps, ramps, or creating complex temperature profiles to simulate processing conditions, the UPP’s fast temperature response will meet your testing needs.

TA’s patented Active Temperature Control (ATC) provides non-contact temperature sensing for active measurement and control of the upper testing surface. A PRT is positioned directly at the sample, in intimate contact with the center of the upper geometry. There is no need for complex calibration procedures and offset tables. Together with the PRT in the lower Peltier plate, the DHR can change the temperature above and below the sample at the same rate for true temperature ramp profiles and data accuracy. Thanks to ATC technology, data obtained with the UPP will match data obtained with other temperature systems, such as the ETC oven.

TA’s patented heat spreader technology conducts heat directly to the sample to ensure uniform sample temperature in vertical and radial directions. Unlike competitive designs, this technology provides accurate measurements at all testing gaps, which facilitates sample loading and sample preparation options, especially for thicker samples.

These technologies work together to deliver a fast and accurate temperature control, delivering increased productivity without compromising the measurement accuracy.

UPP Applications

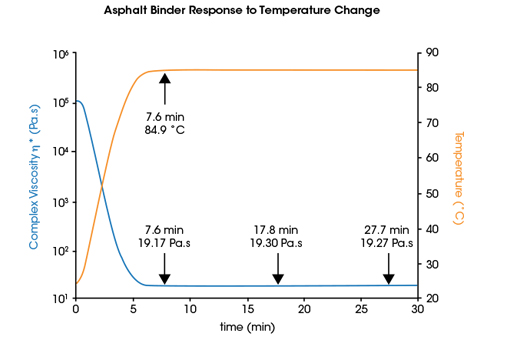

Asphalt binder viscosity

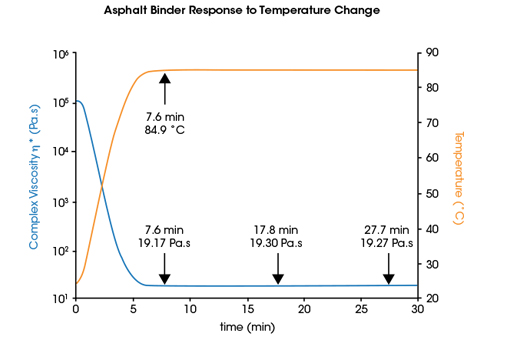

According to federal standards, a sample of asphalt binder needs to be fully equilibrated to within 0.1 °C of the test temperature prior to performing rheological measurements. In the plot shown above, the temperature quickly and accurately jumps from 25 °C to 85 °C within minutes of starting the experiment. The data further shows that as soon as the temperature is within 0.1 °C, the viscosity of asphalt binder is fully equilibrated. No change is seen in the viscosity, even after 20 additional minutes indicating that there is minimal lag between the set-point and real sample temperature. Whether programming temperature steps, ramps or complex thermal profiles to closely simulate processing conditions, the UPP’s fast and precise response reduces the time between tests resulting in increased productivity without compromising the measurement accuracy.

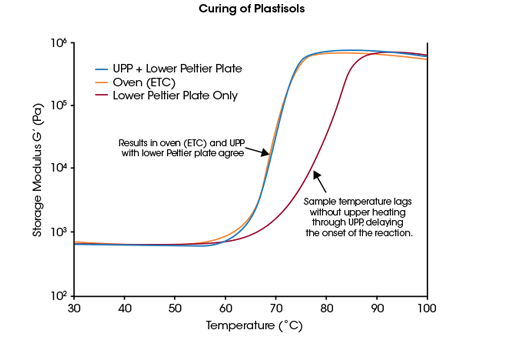

Curing of plastisols

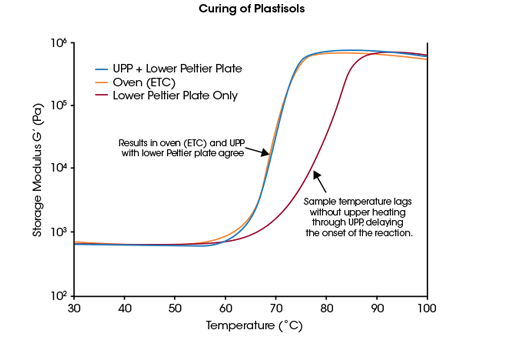

Rheology data is often used to optimize processing conditions, such as identifying operating temperatures, molding cycle times, annealing and many others. Even small errors in temperature, especially non-uniform sample temperatures, lead to erroneous data, the implementation of incorrect processing conditions, and ultimately poor product performance.

The plot shows a temperature ramp on a plastisol using three temperature system configurations, a combined convection-radiation oven (ETC), a lower Peltier Plate only, and a lower Peltier Plate with the Upper Peltier Plate (UPP). A uniform temperature profile in the sample is achieved when the sample is heated from both the top and bottom, as in the ETC and UPP. Data from ETC and UPP configurations exactly match due to uniform heating of the sample from top and bottom. The hardening temperature, observed as a sharp increase in G’, occurs at approximately 60 °C. However, when heating the sample using only the lower Peltier Plate, the sample temperature lags the heating profile resulting in a temperature gradient in the sample. This results in what appears to be a delayed onset of curing at approximately 70 °C. The UPP’s direct temperature control enables users to obtain accurate and precise rheological measurements and unmatched data repeatability, even when compared to different temperature system configurations across their organization.

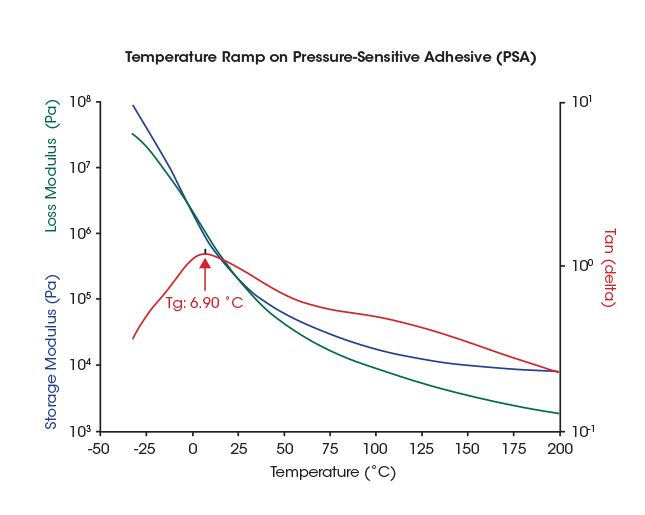

Characterizing adhesives

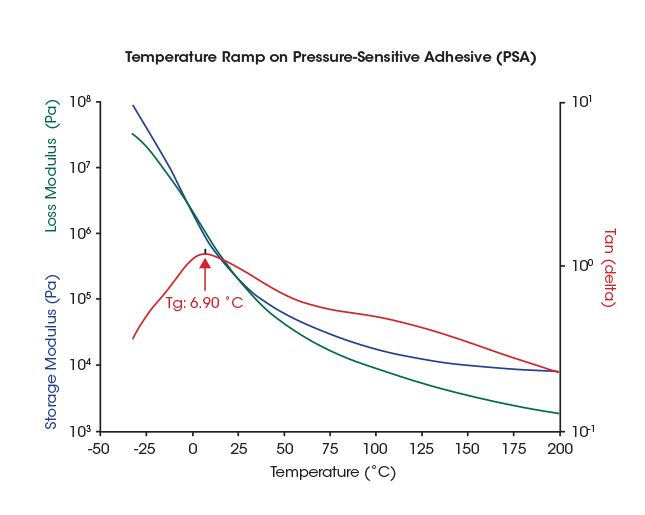

An adhesive’s success and suitability hinges on its ability to bond and resist debonding from a substrate. Measuring the viscoelastic properties, such as G’, G” and tan δ, allow users to quantify performance characteristics such as cohesive strength, tack, and operating temperature range. For example, the performance window of a pressure-sensitive adhesive (PSA) is highly sensitive to the Tg which defines the lowest use temperature of the PSA.

In this PSA example, an oscillation temperature ramp test was performed at 5 °C/min. The peak of the tan δ signal is used to determine the Tg of the material at 6.90 °C, indicating the lowest use temperature. The G’ and G” signals provide quantitative metrics of the cohesive strength and tack of the material from -30 °C to 200 °C. The tack and peel behavior can be further studied using frequency sweeps at the end-use temperatures. The UPP’s simple configuration delivers accurate temperature control, even at sub-ambient temperatures without needing liquid nitrogen or mechanical chillers.

- Description

-

Upper Peltier Plate For Peltier Plate (UPP)

The UPP is a fast-responding temperature control system vital when testing at temperatures away from ambient. Measurement errors upwards of 40% can occur when limiting temperature control to one side of the sample, even at 40 °C, and only grow when moving further from ambient. Using the UPP in conjunction with lower Peltier plates delivers uniform and precise temperature control from -40 °C to 200 °C, eliminating measurement errors in viscosity, yield stress, G’, G”, tan δ, and other rheological data.

The UPP is the only Peltier-based upper heater technology with direct temperature measurements at the sample, made possible through TA’s patented active temperature control (ATC)1. This technology combines with TA’s patented heat spreader technology2 to drive heat directly to the sample for the most accurate temperature control and material characterization, meeting a wide range of testing needs.

(1) U.S. Patent # 6,931,915(2) U.S. Patent # 7,168,299 - Features

-

Features and Benefits

- Patented heat spreader conducts heat directly to sample, creating a uniform sample temperature and eliminating measurement errors

- Fast-responding temperature control driven by Peltier elements for improved productivity

- Wide operating temperature range from -40 °C to 200 °C* in a simple and compact configuration without liquid nitrogen or mechanical chillers

- Direct sample temperature measurement with patented ATC delivers unmatched data reproducibility with oven systems (ETC and FCO)

- Protect samples from environmental influences:

- Solvent reservoir option: prevents evaporation for aqueous and volatile samples

- Thermal shield: protects from moisture condensation

- Gas purge ports: prevent degradation with inert atmosphere

- Compatible with additional accessories to meet every testing need:

- All Peltier plates, including disposable and screw-in plates

- UV curing accessories

- Modular microscope (MMA)

- Optics plate accessory (OPA)

* Testing up to 200 °C requires HT-APP with the UPP

- Technology

-

Technology

The UPP’s innovative Peltier-element design maximizes the speed of temperature response and delivers access to sub-ambient temperatures without liquid nitrogen or expensive fluid circulator setups. Whether programming temperature steps, ramps, or creating complex temperature profiles to simulate processing conditions, the UPP’s fast temperature response will meet your testing needs.

TA’s patented Active Temperature Control (ATC) provides non-contact temperature sensing for active measurement and control of the upper testing surface. A PRT is positioned directly at the sample, in intimate contact with the center of the upper geometry. There is no need for complex calibration procedures and offset tables. Together with the PRT in the lower Peltier plate, the DHR can change the temperature above and below the sample at the same rate for true temperature ramp profiles and data accuracy. Thanks to ATC technology, data obtained with the UPP will match data obtained with other temperature systems, such as the ETC oven.

TA’s patented heat spreader technology conducts heat directly to the sample to ensure uniform sample temperature in vertical and radial directions. Unlike competitive designs, this technology provides accurate measurements at all testing gaps, which facilitates sample loading and sample preparation options, especially for thicker samples.

These technologies work together to deliver a fast and accurate temperature control, delivering increased productivity without compromising the measurement accuracy.

- Applications

-

UPP Applications

Asphalt binder viscosity

According to federal standards, a sample of asphalt binder needs to be fully equilibrated to within 0.1 °C of the test temperature prior to performing rheological measurements. In the plot shown above, the temperature quickly and accurately jumps from 25 °C to 85 °C within minutes of starting the experiment. The data further shows that as soon as the temperature is within 0.1 °C, the viscosity of asphalt binder is fully equilibrated. No change is seen in the viscosity, even after 20 additional minutes indicating that there is minimal lag between the set-point and real sample temperature. Whether programming temperature steps, ramps or complex thermal profiles to closely simulate processing conditions, the UPP’s fast and precise response reduces the time between tests resulting in increased productivity without compromising the measurement accuracy.

Curing of plastisols

Rheology data is often used to optimize processing conditions, such as identifying operating temperatures, molding cycle times, annealing and many others. Even small errors in temperature, especially non-uniform sample temperatures, lead to erroneous data, the implementation of incorrect processing conditions, and ultimately poor product performance.

The plot shows a temperature ramp on a plastisol using three temperature system configurations, a combined convection-radiation oven (ETC), a lower Peltier Plate only, and a lower Peltier Plate with the Upper Peltier Plate (UPP). A uniform temperature profile in the sample is achieved when the sample is heated from both the top and bottom, as in the ETC and UPP. Data from ETC and UPP configurations exactly match due to uniform heating of the sample from top and bottom. The hardening temperature, observed as a sharp increase in G’, occurs at approximately 60 °C. However, when heating the sample using only the lower Peltier Plate, the sample temperature lags the heating profile resulting in a temperature gradient in the sample. This results in what appears to be a delayed onset of curing at approximately 70 °C. The UPP’s direct temperature control enables users to obtain accurate and precise rheological measurements and unmatched data repeatability, even when compared to different temperature system configurations across their organization.

Characterizing adhesives

An adhesive’s success and suitability hinges on its ability to bond and resist debonding from a substrate. Measuring the viscoelastic properties, such as G’, G” and tan δ, allow users to quantify performance characteristics such as cohesive strength, tack, and operating temperature range. For example, the performance window of a pressure-sensitive adhesive (PSA) is highly sensitive to the Tg which defines the lowest use temperature of the PSA.

In this PSA example, an oscillation temperature ramp test was performed at 5 °C/min. The peak of the tan δ signal is used to determine the Tg of the material at 6.90 °C, indicating the lowest use temperature. The G’ and G” signals provide quantitative metrics of the cohesive strength and tack of the material from -30 °C to 200 °C. The tack and peel behavior can be further studied using frequency sweeps at the end-use temperatures. The UPP’s simple configuration delivers accurate temperature control, even at sub-ambient temperatures without needing liquid nitrogen or mechanical chillers.

- Video

-