Using Rheology to Determine the Perfect Viscosity of Gravy

Jennifer Vail | Sarah Cotts

December 18, 2023

On holiday tables across the world, an unexpected unsung hero can make or break the meal: gravy. The seemingly simple condiment adds a dash of flavor to the star roast, livens up potatoes, and can rescue even the driest turkey that may accidentally make its way to the table. But not all gravies are created equal, and not everyone has the same preferences when it comes to their gravy. Thick? Smooth? How it pours over your meal? Rheology, the science of the flow of matter, offers us insight into the gravy on your holiday table.

Using the Discovery™ HR30 hybrid rheometer with a concentric cylinder cup, two types of gravy were tested. Canned gravy, formulated to be shelf-stable, and premium gravy, with a higher protein content, were tested with flow sweeps and temperature ramps.

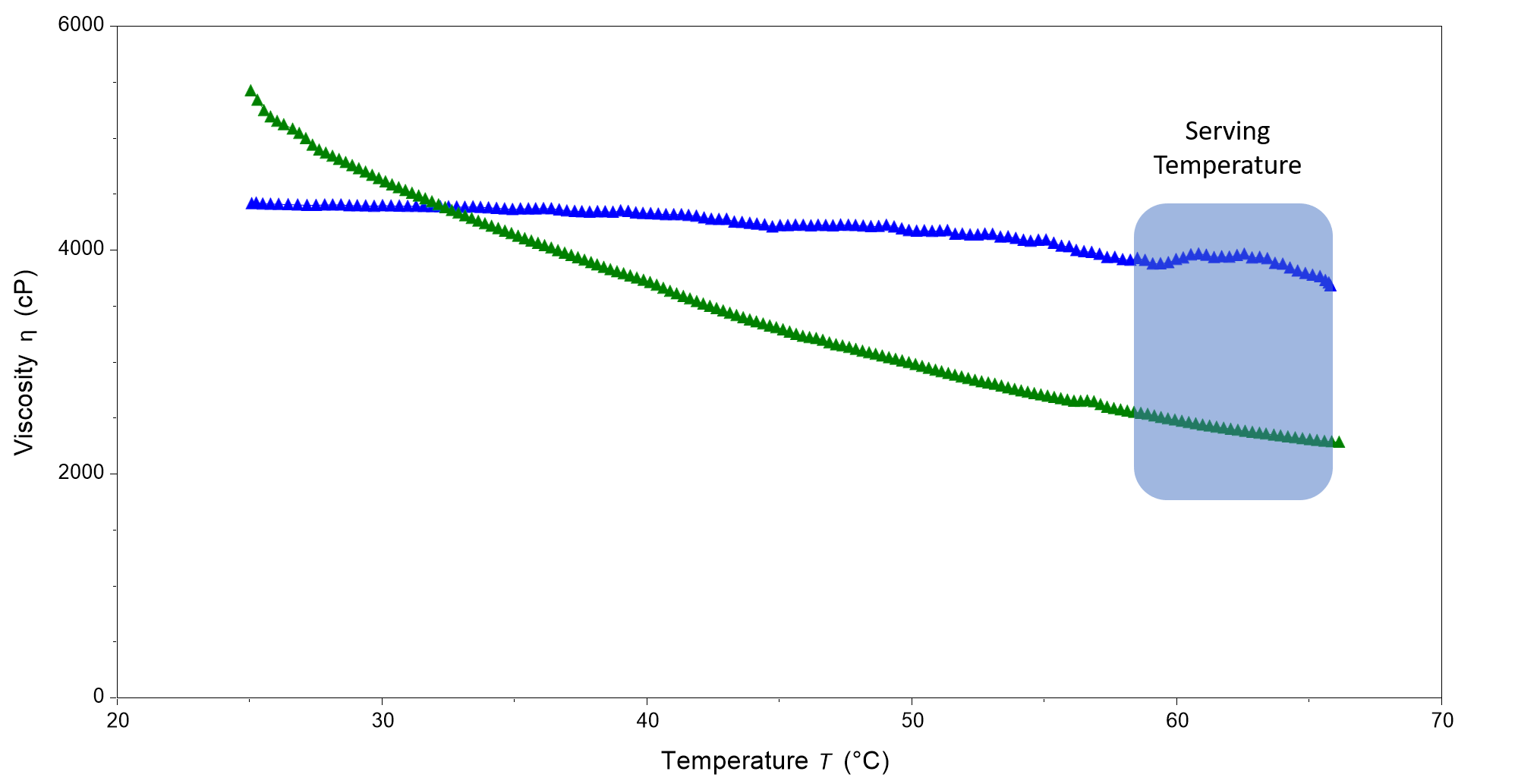

The premium gravy experienced more change in viscosity with temperature than the canned gravy did, likely due to differences in their composition. Canned gravy’s “thickness” is created with thickeners like starch, which create a viscoelastic network that doesn’t change with temperature. This is advantageous for this product, which is shipped and stored at ambient temperature. The ability to maintain the same rheological properties over a range of temperatures helps maintain the dispersion preventing phase separation. But the “thickness” of the premium gravy is a combination of thickeners like starch and dissolved protein. Protein’s impact on viscosity is very temperature dependent. So, depending on the pour or thickness you prefer, you may want to take extra care with the temperature at which you serve the premium gravy!

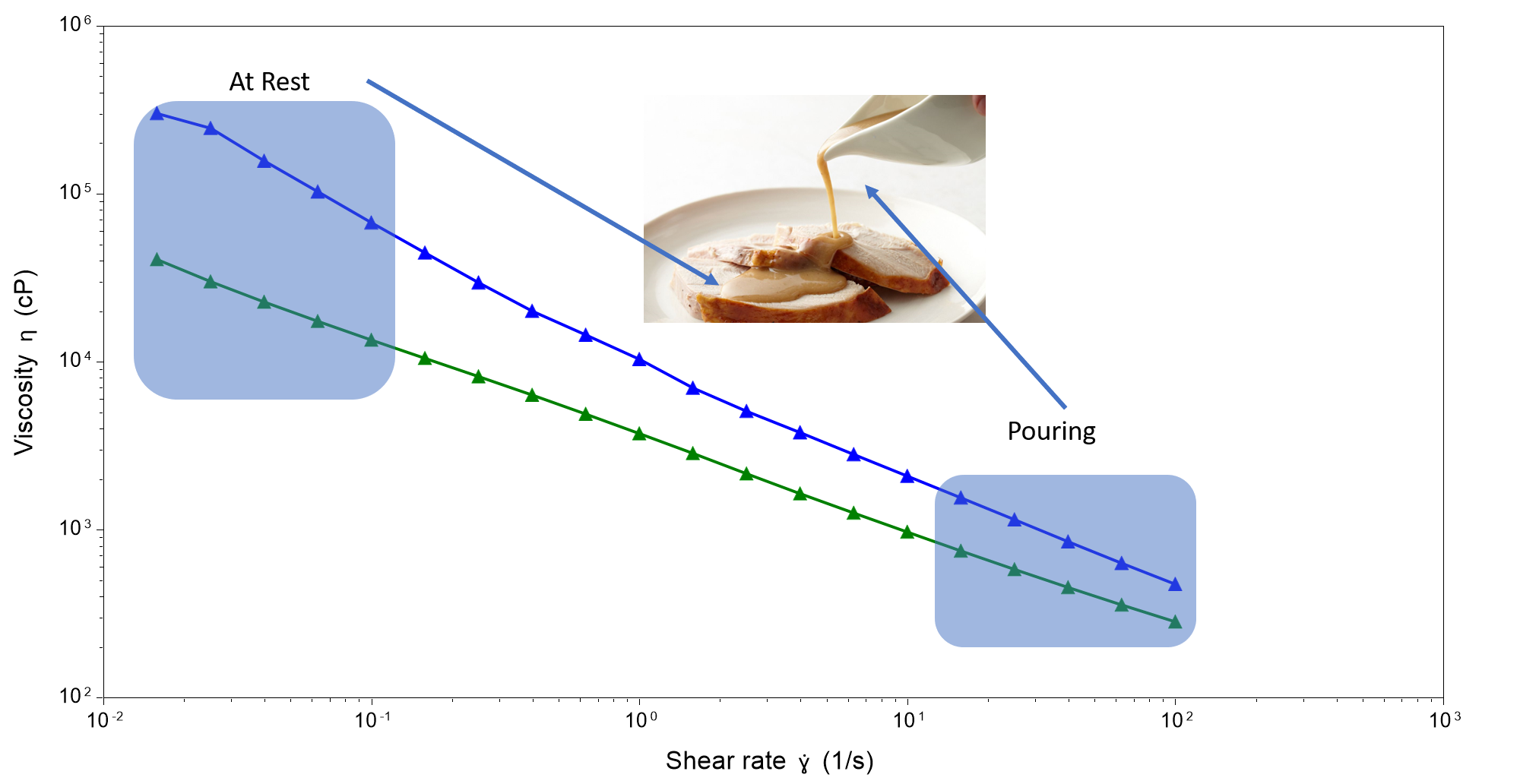

Both gravies exhibit shear-thinning, an important property for gravy and many other foods. Lower viscosity at high shear rates allows us to easily pour it to coat our food. The higher viscosity at low shear rates prevents the gravy from running off the side of the turkey, or allows it to sit on top of the mashed potatoes without soaking in.

In the shear rate range associated with pouring (10 to 100 sec-1), the canned gravy’s viscosity is nearly two times that of the premium gravy (1,100 cP vs. 600 cP). While this difference is easily detected on a rheometer, guests at your holiday dinner likely will not perceive any difference as they’re pouring.

They will, however, notice effects seen in the lower shear rates (0.01 to 0.1 sec-1). These shear rates represent how gravy behaves after pouring, as it slowly spreads to coat the food. In this process, the canned gravy’s viscosity is seven times greater than the premium gravy (175,000 cP vs. 25,000 cP). Your guests will definitely be able to see that difference! And if the low shear viscosity is too low, the gravy could even be perceived as watery and thin. But if it’s too high, it will appear gelatinous or paste-like.

With food, and rheology, there’s no single right value. Some prefer the lower-viscosity gravy to get a uniform coating, and some prefer the higher viscosity to get more gravy on each bite. What do you prefer on your table?

Other Resources

- Application Note – Determine Viscoelasticity and Spreadability of Cream Cheese

- Application Note – Rheological Characterization of Yogurt

- Application Note – Evaluating the Flow Behavior of Molten Chocolate

- Webinar – Neil Cunningham: Essential tools for the new Rheologist

- Webinar – Applications of Tribo Rheometry in Material Characterization

- Package – Food Testing Materials Lab Package

- Blog – What are Rheometry and Rheology?