UV Curing Accessories

UV-curable materials are widely used for coatings, adhesives, and inks. When these materials are exposed to UV radiation, a fast cross-linking reaction occurs, typically within less than a second to a few minutes. Two Smart Swap™ accessories for rheological characterization of these materials are available for the DHR rheometer. One accessory uses a light guide and reflecting mirror assembly to transfer UV radiation from a high-pressure mercury light source. The second accessory uses self-contained light emitting diodes (LED) arrays to deliver light to the sample. The UV Curing accessories include 20 mm quartz plate, UV light shield, and nitrogen purge cover. Optional temperature control using the Upper Peltier Plate (UPP) to a maximum of 150 °C is available. Disposable plates are available for hard UV coatings, which cannot be removed from the plates once cured.

UV Light Guide Accessory Technology

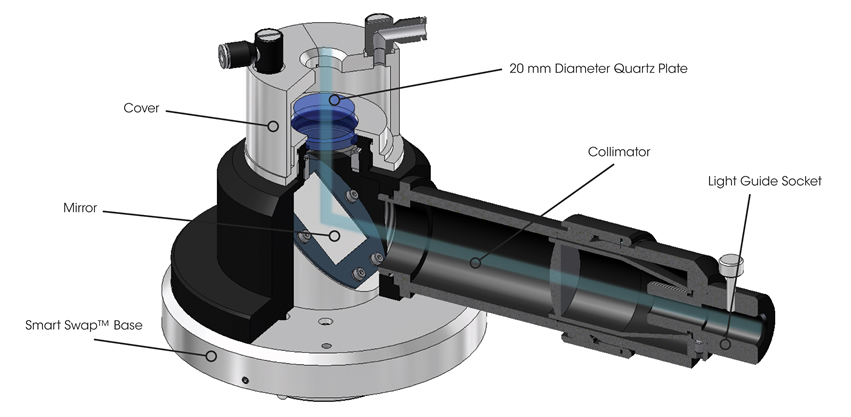

UV Light Guide Accessory Technology

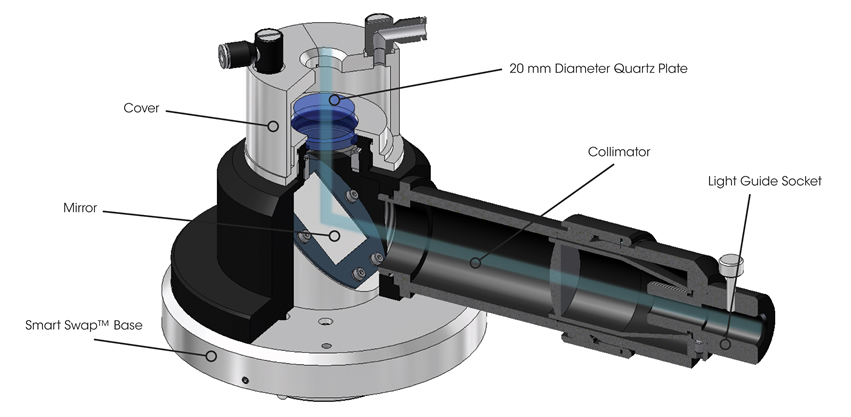

The UV Light Guide accessory includes a lower Smart Swap™ assembly with quartz plate, light source mount, collimator, 5 mm diameter light guide, and UV mercury lamp source (Excelitas Omnicure S2000). It provides a broad wavelength spectrum from 320 nm to 500 nm, with a primary peak at 365 nm. The maximum output intensity is greater than 300 mW/cm2. External filter holder and filters are available for the light source.

Features and Benefits

- Smart Swap™ technology

- Convenient compact

- Collimated light and mirror assembly ensure uniform irradiance across plate diameter

- Maximum intensity at plate 300 mW/cm2

- Broad range spectrum with main peak at 365 nm

- One system with specific wavelengths accessible through filtering options

- Cover with nitrogen purge ports

- Optional disposable acrylic plates

- Optional temperature control using the Upper Peltier Plate (UPP) to 150 ˚C

- Software programmable trigger time and intensity

UV LED Accessory Technology

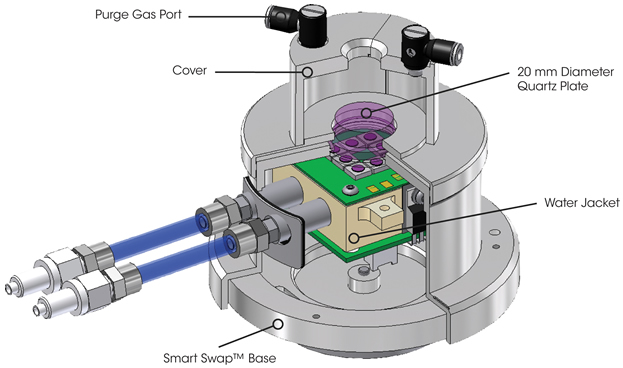

UV LED Accessory Technology

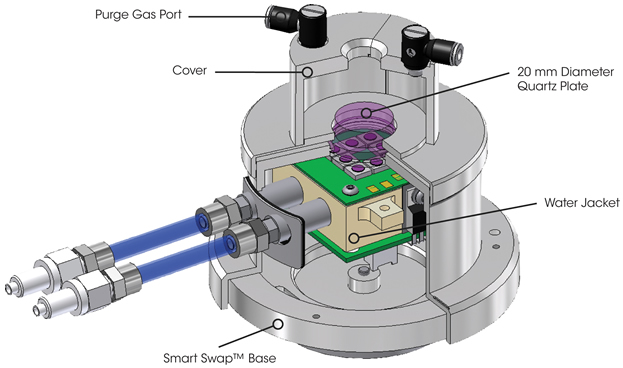

The UV LED accessories use arrays of light emitting diodes that provide single peak wavelength light sources. The LED array is mounted on a PCB and is fixed to a water jacket that cools the LED’s during use. Like the UV light guide system, LED’s are pre-aligned to ensure uniform irradiance across the surface of the plate. There are two LED accessories available at wavelengths of 365 nm and 455 nm. The maximum output UV intensity is 150 mW/cm2 and 350 mW/cm2, respectively. They are fully integrated with the rheometer through a Smart Swap™ option. Trigger time and intensity are conveniently programmed through the software.

Features and Benefits

- Smart Swap™ technology

- New technology replaces mercury bulb systems

- 365 nm wavelength with peak intensity of 150 mW/cm2

- 455 nm wavelength with peak intensity of 350 mW/cm2

- No intensity degradation over time

- Even intensity across plate diameter, LED positioned directly below plate

- Compact and fully integrated design including power, intensity settings and trigger

- Cover with Nitrogen purge ports

- Optional disposable Acrylic plates

- Optional temperature control using the Upper Peltier Plate (UPP) to 150 ˚C

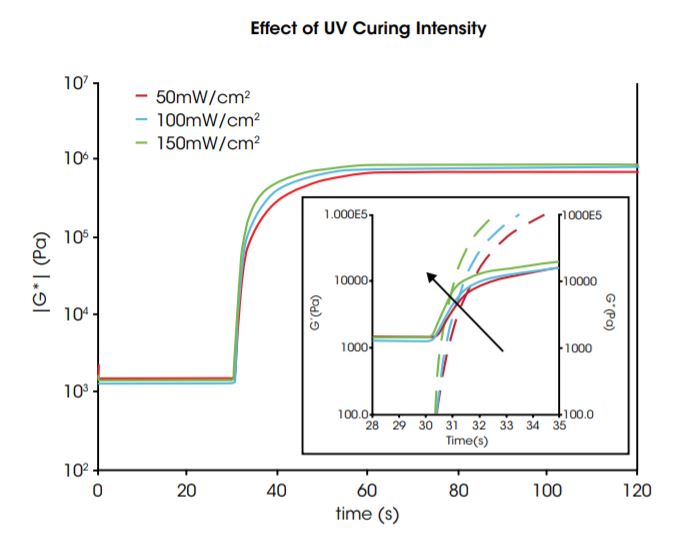

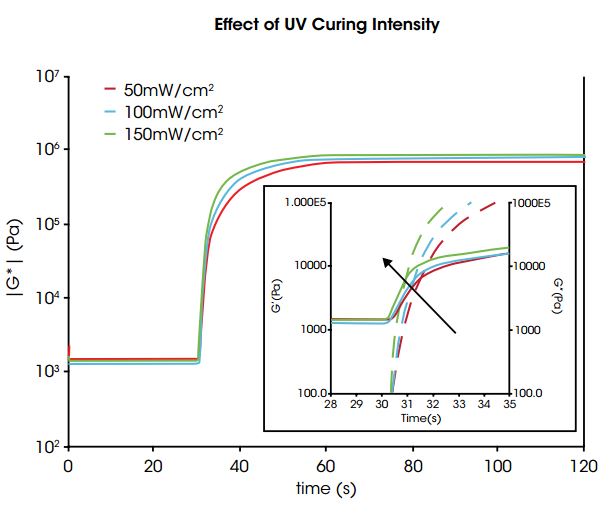

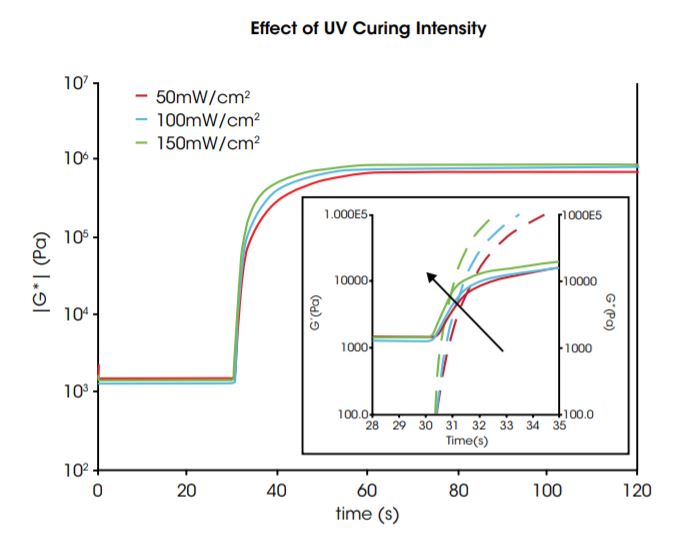

UV Accessory Application

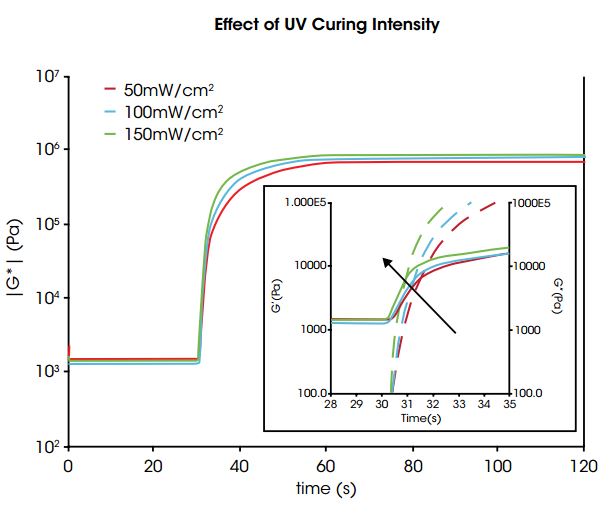

These accessories allow the study of UV curing reactions by monitoring the elastic (G’) and viscous (G”) moduli. The example on the left shows results of a pressure sensitive adhesive, (PSA), characterized with the UV Light Guide Accessory. The PSA was held at an isothermal temperature of 25 °C and the curing profile was measured at radiation intensities from 50 mW/cm² to 150 mW/cm². The sample is measured for 30 seconds before the light is turned on. The data show faster reaction kinetics with increasing intensity, as evidenced by the shorter time for crossover of G’ and G”. Similar results can be obtained with controlled temperature, where the reaction is seen to occur more quickly at higher temperatures. The curing reaction happens in less than two seconds. The fast data acquisition of the Discovery Hybrid Rheometers (up to 50 pts/sec) enables clear identification of the liquid to solid transition. Note that changing the intensity and temperature by small amounts shifts the crossover point by a fraction of a second. This information is important for understanding adhesive control parameters for high-speed UV curing processes, as well as for understanding differences in initiators when formulating materials.

- Description

-

UV Curing Accessories

UV-curable materials are widely used for coatings, adhesives, and inks. When these materials are exposed to UV radiation, a fast cross-linking reaction occurs, typically within less than a second to a few minutes. Two Smart Swap™ accessories for rheological characterization of these materials are available for the DHR rheometer. One accessory uses a light guide and reflecting mirror assembly to transfer UV radiation from a high-pressure mercury light source. The second accessory uses self-contained light emitting diodes (LED) arrays to deliver light to the sample. The UV Curing accessories include 20 mm quartz plate, UV light shield, and nitrogen purge cover. Optional temperature control using the Upper Peltier Plate (UPP) to a maximum of 150 °C is available. Disposable plates are available for hard UV coatings, which cannot be removed from the plates once cured.

- Technology

-

UV Light Guide Accessory Technology

UV Light Guide Accessory Technology

The UV Light Guide accessory includes a lower Smart Swap™ assembly with quartz plate, light source mount, collimator, 5 mm diameter light guide, and UV mercury lamp source (Excelitas Omnicure S2000). It provides a broad wavelength spectrum from 320 nm to 500 nm, with a primary peak at 365 nm. The maximum output intensity is greater than 300 mW/cm2. External filter holder and filters are available for the light source.

Features and Benefits

- Smart Swap™ technology

- Convenient compact

- Collimated light and mirror assembly ensure uniform irradiance across plate diameter

- Maximum intensity at plate 300 mW/cm2

- Broad range spectrum with main peak at 365 nm

- One system with specific wavelengths accessible through filtering options

- Cover with nitrogen purge ports

- Optional disposable acrylic plates

- Optional temperature control using the Upper Peltier Plate (UPP) to 150 ˚C

- Software programmable trigger time and intensity

UV LED Accessory Technology

UV LED Accessory Technology

The UV LED accessories use arrays of light emitting diodes that provide single peak wavelength light sources. The LED array is mounted on a PCB and is fixed to a water jacket that cools the LED’s during use. Like the UV light guide system, LED’s are pre-aligned to ensure uniform irradiance across the surface of the plate. There are two LED accessories available at wavelengths of 365 nm and 455 nm. The maximum output UV intensity is 150 mW/cm2 and 350 mW/cm2, respectively. They are fully integrated with the rheometer through a Smart Swap™ option. Trigger time and intensity are conveniently programmed through the software.

Features and Benefits

- Smart Swap™ technology

- New technology replaces mercury bulb systems

- 365 nm wavelength with peak intensity of 150 mW/cm2

- 455 nm wavelength with peak intensity of 350 mW/cm2

- No intensity degradation over time

- Even intensity across plate diameter, LED positioned directly below plate

- Compact and fully integrated design including power, intensity settings and trigger

- Cover with Nitrogen purge ports

- Optional disposable Acrylic plates

- Optional temperature control using the Upper Peltier Plate (UPP) to 150 ˚C

- Applications

-

UV Accessory Application

These accessories allow the study of UV curing reactions by monitoring the elastic (G’) and viscous (G”) moduli. The example on the left shows results of a pressure sensitive adhesive, (PSA), characterized with the UV Light Guide Accessory. The PSA was held at an isothermal temperature of 25 °C and the curing profile was measured at radiation intensities from 50 mW/cm² to 150 mW/cm². The sample is measured for 30 seconds before the light is turned on. The data show faster reaction kinetics with increasing intensity, as evidenced by the shorter time for crossover of G’ and G”. Similar results can be obtained with controlled temperature, where the reaction is seen to occur more quickly at higher temperatures. The curing reaction happens in less than two seconds. The fast data acquisition of the Discovery Hybrid Rheometers (up to 50 pts/sec) enables clear identification of the liquid to solid transition. Note that changing the intensity and temperature by small amounts shifts the crossover point by a fraction of a second. This information is important for understanding adhesive control parameters for high-speed UV curing processes, as well as for understanding differences in initiators when formulating materials.