Why Rheology is Relevant and Accessible: Dispelling 5 Myths About Rheology

Morgan Ulrich | Sarah Cotts | Alina Latshaw

April 10, 2025

Will your paint stick to the wall or drip off? Does your low-fat cream cheese have the same texture as a full-fat version? How will new ingredients affect your formulation’s texture and application, especially as environmental conditions change? Rheology offers invaluable insights that help researchers, developers, and engineers across numerous industries optimize their products for performance and customer satisfaction.

Rheology is the study of the flow and deformation of materials. If rheology seems overwhelming, you’re not alone. Many labs shy away from comprehensive rheological insights for a number of reasons. But this technique is essential for optimizing processing conditions, predicting product performance, designing delivery methods and storage conditions, and assessing the impact of additives and fillers. Rheology is critical for optimizing various products during formulation, material selection, processing, and final use. Learn the truth about rheology as we dispel five common myths below.

Myth #1: I Don’t Need a Rheometer, a Viscometer is Good Enough

Many labs use viscometers, which measure viscosity under one type of application. But what happens when that viscosity changes during mixing, storage, or spreading, like in creams or emulsions?

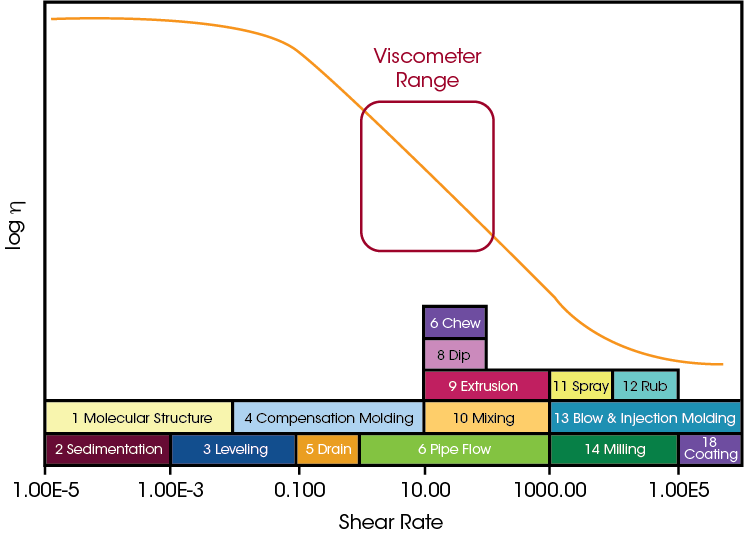

Rheometers measure viscosity across a wide range of conditions, or shear rates, measuring how samples change with applied stress.i Think about shaving cream: it gets thicker when you shake the can, pump it out, and rub it onto skin, but it becomes more liquid-like at rest. Hair conditioner is also thick in the bottle (zero shear), flows smoothly when it’s pumped out (increased shear), thick when it sits in your hand (zero shear), then thin and spreadable when you comb it through your hair (high shear).

Varying the shear rate allows rheometers to measure viscosity at all those different stages of use. One critical measurement is zero shear rheology, which predicts product behavior during storage and low-flow applications. Zero shear rheology is essential for assessing product stability. For example, will a cream’s ingredients separate and settle during shipping and storage? Delivering consistent, stable products requires zero shear rheology, a measurement that viscometers cannot provide.

Additionally, rheometers measure yield stress, the amount of stress required to initiate flow.ii Yield stress can help measure thickness and predict the stability of a material. A higher yield stress prevents phase separation, sedimentation, or aggregation. But too high of a yield stress means the material cannot flow through a pump. For example, paint pigments can separate with too low of a yield stress, resulting in an uneven color; however, paint with too high of a yield stress cannot be used in spray applications.

Finally, rheometers also quantify viscoelasticity, a measure of a material’s internal structure – how soft or rigid it is. Viscoelasticity is important for predicting customer sensory perception, successful coating and pumping processes, and packaging design.

Since rheometers measure more than just viscosity, they offer a critical advantage in optimizing formulations and accelerating product development for applications like battery slurries, pharmaceutical topicals, coatings, food, and personal care products.

Myth #2: Rheometers are Difficult to Operate

Rheology is a notoriously complex field, combining mathematics and physics to characterize materials. For inexperienced users, rheology can seem like a massive challenge. Luckily, new technology simplifies rheology down to its core so you can get essential analysis without difficult training, measurements, or calculations.

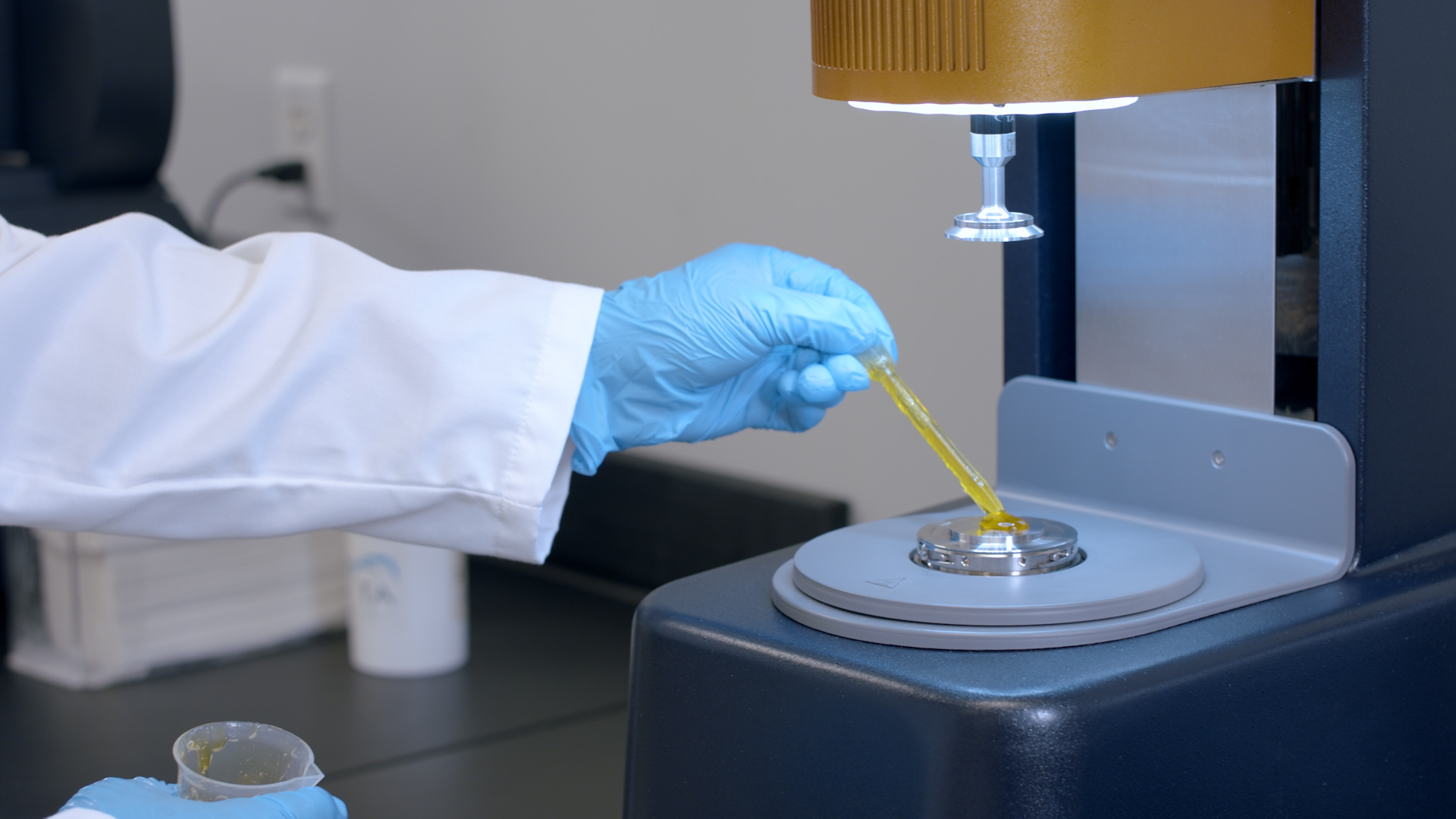

The new Discovery Core Rheometer empowers users of all levels to perform reliable, efficient rheological measurements. RheoGuide™ software guides the user through testing: simply select a method from the app-style touch screen and let the instrument guide you through a successful experiment. Test methods are customizable for your needs, plus easily synchronized across labs worldwide, providing consistent operation and data you can trust.

The Discovery Core Rheometer is designed to prevent common sources of operator error with automatic gap control and validation throughout testing. Additionally, automated results analysis eliminates the need for manual data processing. From loading a sample to analyzing data, the Discovery Core Rheometer makes rheology simple for all users. See the Discovery Core Rheometer in action in this demonstration video.

Myth #3: Rheology Data is Hard to Understand

Rheology data may seem daunting, but new technology simplifies analysis so you can easily relate rheology data back to your quality control metrics.

The Discovery Hybrid Rheometers offer automated analysis in TRIOS software, reporting your specified product-relevant key performance indicators immediately after a test. TRIOS automatically generates custom reports including experimental details, data plots and tables, and analysis results. And data can be exported in a variety of file formats, including new JSON export capability as well as images and PowerPoint files, giving you the flexibility to save and present your data in seconds.

The Discovery Core Rheometer is designed for even more simplicity in analysis, with RheoGuide software automating analysis for quick quality assurance and quality control tests. With custom methods, the Discovery Core Rheometer can instantly indicate Pass or Fail based on your specifications.

Automation on the Discovery Hybrid Rheometer and Discovery Core Rheometer make it easy to quickly report the metrics that matter for your material, such as how thick your lotion is or whether your paint is at risk of sedimentation in storage.

Myth #4: Rheology is Only Relevant for Liquids & Flow Behavior

At this point, we have mostly covered what rheology can measure for liquids – but did you know it doesn’t stop there? If you thought rheology does not apply to your material, you thought wrong.

Rheology measures critical properties of a variety of materials, including powders and solids. Powder rheology measures dynamic flowability and shear properties of consolidated powder under ambient conditions or controlled temperature. Screening incoming powder materials or new formulations can prevent large-scale production issues during storage, pouring, and gravity dispensing in a hopper. And understanding how changes in particle size or supplier source can help engineers accelerate new product development. For example, the differences in flow and cohesion of two different powder excipients reveals that one is better for pharmaceutical product processing. Other examples include powder coatings and battery anode slurries.

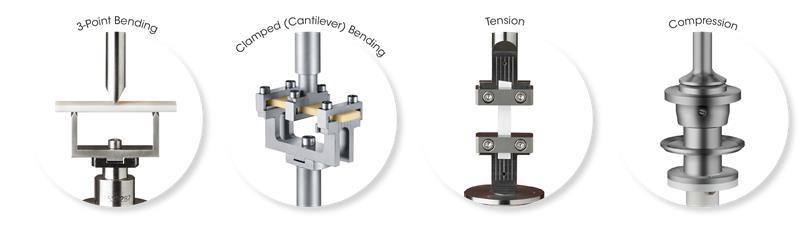

The Discovery Hybrid Rheometer also delivers accurate Dynamic Mechanical Analysis (DMA) data for testing solid and soft-solid materials. A variety of accessories enable tests of materials under bending, linear tension, compression, and torsion. DMA mode is ideal for identifying a material’s transition temperatures and provides reliable measurements over the instrument’s full range of temperatures and humidity. This capability is only made possible thanks to the unique magnetic bearing technology used in TA Instrument’s Discovery Hybrid Rheometer. The combination of linear DMA testing and rotational rheological characterization on a single platform can be useful for key applications such as: studying curing and compression strength of hydrogels, characterizing processability and crystallization of plastics, and curing and strength of composites.

Myth #5: All Rheometers are Basically the Same

All rheometers are not created equal.

TA Instruments rheometers are the top choice of leading labs around the world because of their industry-leading motors. Both the Discovery Hybrid Rheometer and Core Rheometer are built for high performance with drag cup motors that enable shear rheology in controlled stress rate or strain modes.

The Discovery Core Rheometer is more accessible in both cost and usability, suiting the needs of quality control labs looking for quick, reliable rheological measurements. The Discovery Hybrid Rheometer is built for higher performance in research and development labs, offering more flexibility and an Advanced Drag Cup Motor for an even wider range of measurement frequencies, material types, and experimental designs. When considering rheometers, ask yourself: Do I need comprehensive control to design experiments and analyze data? Or do I place more importance on accessibility and usability with simplified testing?

Rheometer Reflections and Resources

Clearly, top research and quality labs rely on rheometers for a reason: rheometers unlock complete characterization of material flow and deformation across a wide range of application-relevant conditions. And leading technology empowers users of all experience levels to seamlessly incorporate rheology into their workflows.

Learn more about the Discovery Hybrid Rheometer and Discovery Core Rheometer, the two leading rheometers offering unparalleled reliability and accessibility. Contact TA Instruments to explore your options and find a rheometer that matches your labs’ capabilities and analysis requirements.

ihttps://www.britannica.com/science/shear-wave#ref895380:~:text=Shear%20is%20the%20change%20of%20shape%2C%20without%20change%20of%20volume%2C%20of%20a%20layer%20of

%20the%20substance%2C%20produced%20by%20a%20pair%20of%20equal%20forces%20acting%20in%20opposite%20directions%20along%20the%20

two%20faces%20of%20the%20layer

iihttps://www.tainstruments.com/pdf/literature/RH025.pdf

Other Resources

- Product – Discovery Core Rheometer

- Product – Discovery Hybrid Rheometers

- Blog – Viscometer vs Rheometer: Discover Why a Rheometer Offers More Than Just Viscosity Measurement

- Application Note – Introduction to Polymer Melt Rheology and Its Application in Polymer Processing

- Application Note – Shear and Flow Properties of an NMC Based Dry Cathode Powder